Discover the fascinating world of thermocouples, those unsung heroes of temperature measurement. From the frigid depths of cryogenics to the blazing heat of industrial furnaces, these ingenious devices provide crucial temperature data across countless applications. This guide dives deep into the science behind thermocouples, explores various types and applications, and equips you with the knowledge to select, install, and troubleshoot these essential tools. Discover the precise temperature readings you need with a comprehensive 407c pt chart. Transform your garage with a durable and stylish upgrade by exploring the polyurea garage floor coating cost options available.

Decoding the Science: How Thermocouples Work

At the heart of every thermocouple lies a fundamental principle of physics: the Seebeck effect. Discovered in 1821 by Thomas Johann Seebeck, this effect describes the generation of a voltage across two dissimilar metals joined at one end (the “hot junction”) when a temperature difference exists between the hot junction and the other ends (the “cold junction”). This voltage, directly proportional to the temperature difference, provides the basis for thermocouple operation. Think of it as heat transforming into a measurable electrical signal.

A Thermocouple for Every Need: Exploring the Types

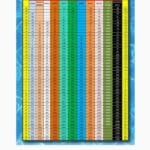

Just as a carpenter wouldn’t use a hammer for every task, different temperature measurement scenarios call for specific thermocouple types. Each type, designated by a letter (e.g., K, J, T, E, N, R, S, B), represents a unique combination of metal alloys, each with its own temperature range, sensitivity, and application niche. Selecting the right type is paramount for accurate and reliable measurements. The table below provides a comparison of common thermocouple types:

| Type | Metals | Temperature Range (°C) | Common Applications |

|---|---|---|---|

| K | Chromel-Alumel | -200 to 1250 | Ovens, furnaces, industrial uses |

| J | Iron-Constantan | -210 to 760 | Lower-temperature industrial processes, gas appliances |

| T | Copper-Constantan | -270 to 400 | Refrigeration, air conditioning |

| E | Chromel-Constantan | -270 to 1000 | High output voltage, vacuum applications |

| N | Nicrosil-Nisil | -270 to 1300 | High-temperature oxidizing/inert atmospheres |

| R | Platinum-Rhodium (13%) | 0 to 1768 | High-temperature measurements, oxidizing atmospheres |

| S | Platinum-Rhodium (10%) | 0 to 1768 | Similar to Type R |

| B | Pt-Rh(30%)-Pt-Rh(6%) | 0 to 1820 | Very high temperatures, ceramic industry |

Thermocouple Construction: A Closer Look

Thermocouples are more than just two wires twisted together. Their construction, including the junction type (grounded, ungrounded, exposed), insulation, and protective sheath, significantly impacts their performance and suitability for specific environments. Grounded junctions offer swift response times but may be susceptible to electrical interference. Ungrounded junctions provide electrical isolation, and exposed junctions, while highly responsive, are more fragile. The choice of materials also affects durability, especially in harsh conditions.

Thermocouples in Action: Real-World Applications

Thermocouples are the silent workhorses across numerous industries. In manufacturing, they meticulously monitor furnace temperatures, ensuring product quality. They optimize engine performance in automobiles by tracking exhaust gas temperatures. In our homes, they regulate temperatures in ovens, water heaters, and HVAC systems. From scientific research to everyday appliances, their presence is ubiquitous.

Calibration: The Key to Accurate Measurement

Like any measuring instrument, thermocouples require calibration to maintain accuracy. Various calibration methods exist, from comparisons with known standards to specialized calibration furnaces. Regular calibration is crucial for reliable performance.

Troubleshooting: When Things Go Wrong

Even the most reliable devices can experience issues. Thermocouples might exhibit drift (gradual changes in readings over time), noise (erratic fluctuations), or faulty wiring. Troubleshooting typically involves checking for loose connections, physical damage, or problems with the reference junction compensation.

Potential Problems with a Failing Thermocouple

A failing thermocouple can wreak havoc, causing temperature fluctuations in ovens, pilot light outages in gas appliances, or even a complete system shutdown. For example, imagine your oven temperature swinging wildly during baking—a faulty thermocouple could be the culprit. In gas appliances, a failing thermocouple often extinguishes the pilot light, a crucial safety feature designed to prevent gas leaks if there’s no flame.

Diagnosing a Thermocouple Failure

A multimeter is your essential tool for thermocouple diagnostics. By measuring the millivoltage output when heated, you can determine if the thermocouple is functioning correctly. A low or non-existent voltage suggests a problem. Other issues, like a clogged pilot orifice in gas appliances, can mimic thermocouple failure, so thorough troubleshooting is vital.

Replacing a Thermocouple: A DIY Guide

Replacing a thermocouple is often a manageable DIY project, potentially saving you the cost of a professional service call. However, safety is paramount. Always turn off both the gas and power supply before starting. If you’re unsure at any point, consult a qualified technician.

Here’s a step-by-step guide:

- Safety First! Turn off the gas and power supply to the appliance.

- Locate the Thermocouple: It’s usually near the pilot light assembly.

- Disconnect the Old Thermocouple: Carefully detach it from the gas valve and pilot burner.

- Install the New Thermocouple: Ensure it’s the correct type and securely attach it.

- Relight the Pilot: Follow the manufacturer’s instructions.

- Test: Turn the appliance on and verify proper function.

Weighing the Pros and Cons of Thermocouples

Pros:

- Wide Temperature Range: Suitable for a vast spectrum of applications.

- Durability: Can withstand harsh environments.

- Cost-Effective: Generally affordable compared to other temperature sensors.

Cons:

- Accuracy: May be less accurate than RTDs in some situations.

- Noise Susceptibility: Can be affected by electrical interference.

Choosing Wisely: Thermocouple Selection Criteria

Selecting the right thermocouple involves considering several factors:

- Temperature Range: Match the thermocouple to your application’s temperature range.

- Environment: Consider factors like corrosive chemicals or high pressures.

- Accuracy Requirements: Choose a type that meets your precision needs.

- Budget: Balance performance with cost considerations.

Future Trends in Thermocouple Technology

While the fundamental principles of thermocouples are well-established, research continues to refine materials, fabrication techniques, and applications. Emerging trends include wireless thermocouples, advanced materials for extreme environments, and integration with smart technologies for enhanced monitoring and control. These advancements promise greater accuracy, durability, and versatility in temperature measurement.