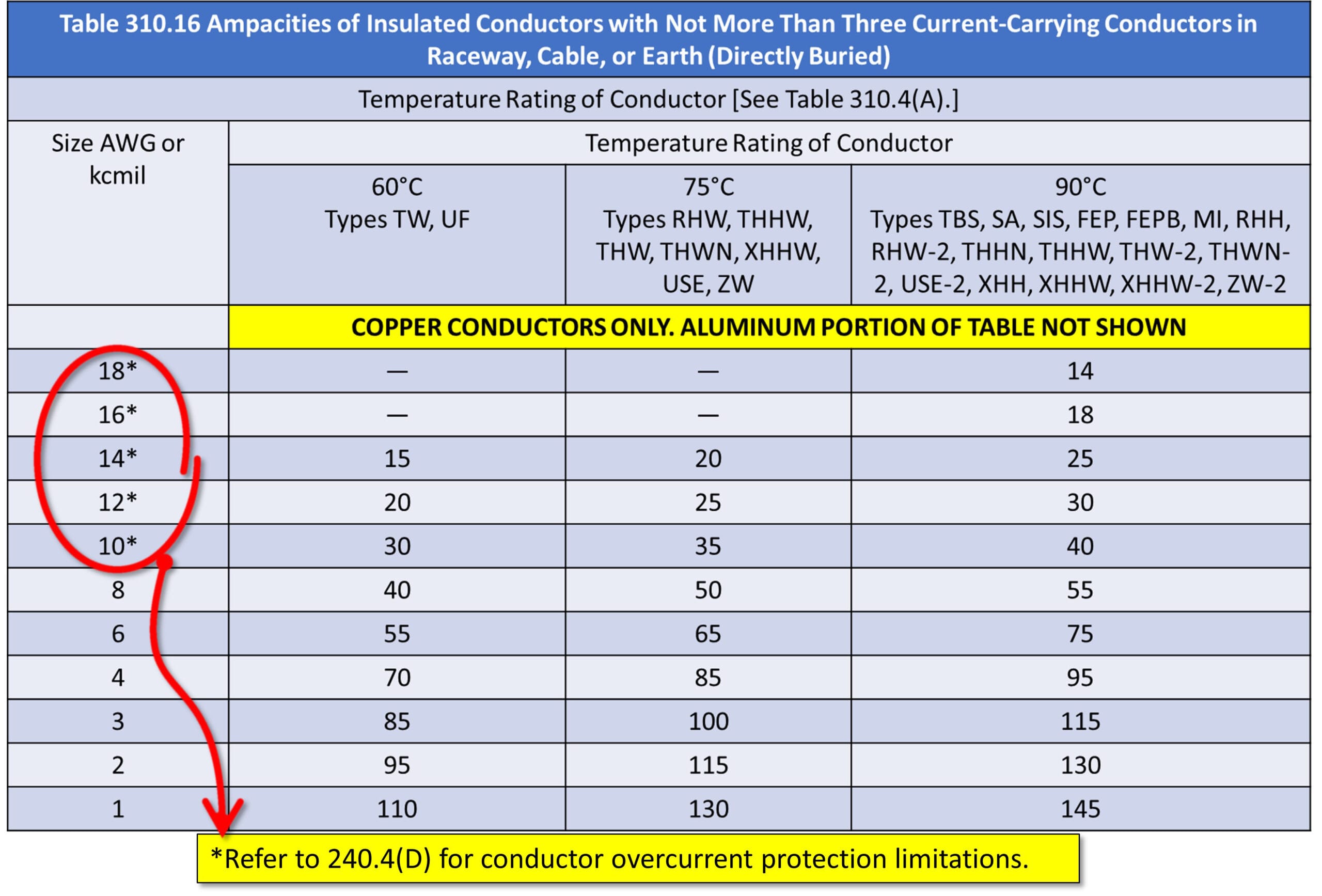

Decoding Conductor Ampacity: NEC Table 310.15(B)(16)

Selecting the correct wire size for an electrical circuit is paramount for safety and performance. This isn’t a matter of guesswork; it’s governed by the National Electrical Code (NEC), specifically Table 310.15(B)(16). This table, formerly known as Table 310.16, provides the allowable ampacities (current-carrying capacities) of insulated conductors, acting as the electrician’s guide to safe wiring practices. Using the correct ampacity prevents overheating, potential fires, and ensures your electrical system operates reliably. This guide will break down the key aspects of Table 310.15(B)(16), empowering you to choose the right wire for any project.

Wire Sizing Fundamentals: Why Ampacity Matters

Imagine trying to force a rushing river through a narrow pipe. The pressure would be immense, right? Electricity flowing through a wire behaves similarly. If the wire is too small (low ampacity) for the current, it overheats, potentially damaging the insulation, creating a fire hazard, and possibly damaging connected equipment. Conversely, an oversized wire is inefficient, costly, and difficult to work with. Table 310.15(B)(16) helps you find the “Goldilocks” wire size – not too big, not too small, but just right.

Factors Influencing Ampacity

Several critical factors influence a wire’s ampacity. Understanding these parameters is crucial for correctly interpreting and applying Table 310.15(B)(16):

- Conductor Material: Copper and aluminum are common conductor materials. Copper offers higher conductivity, allowing a smaller copper wire to carry the same current as a larger aluminum wire. This impacts cost and installation considerations.

- Insulation Type: The insulation surrounding the conductor has a temperature rating. THHN, THWN, XHHW, and other insulation types withstand varying degrees of heat. Choosing the right insulation ensures the wire can operate safely at its rated ampacity.

- Ambient Temperature: Higher ambient temperatures decrease a conductor’s ability to dissipate heat, effectively reducing its ampacity. The NEC mandates derating factors in 310.15(B)(2)(a) to compensate for this effect. This is especially important in hot environments or when wires are bundled together.

- Number of Conductors: Heat builds up when multiple conductors are bundled in a raceway or cable. Table 310.15(B)(16) applies specifically to three or fewer current-carrying conductors. For more than three, adjustment factors from Table 310.15(B)(3)(a) must be applied to avoid exceeding safe operating temperatures.

Mastering Table 310.15(B)(16): A Step-by-Step Guide

Using Table 310.15(B)(16) may appear complex at first glance, but it’s straightforward once you grasp the underlying principles. Follow these steps to determine the correct wire size:

- Identify Conductor Material: Determine if your wire is copper or aluminum.

- Determine Insulation Type: Note the insulation type (e.g., THHN, THWN-2).

- Assess Ambient Temperature: Measure or estimate the highest expected temperature surrounding the wire.

- Count Conductors: Determine the number of current-carrying conductors in the raceway or cable.

- Consult the Table: Locate the row corresponding to your wire’s material and insulation. Find the column matching your ambient temperature and number of conductors. The value at the intersection is the allowable ampacity.

- Apply Derating Factors: If more than three conductors are present or the ambient temperature exceeds the table’s base value, apply the appropriate derating factors from NEC 310.15(B)(2)(a) and 310.15(B)(3)(a).

Avoiding Common Pitfalls

Even seasoned professionals can make mistakes when using Table 310.15(B)(16). Here are common errors to avoid:

- Overlooking Ambient Temperature: Neglecting to account for ambient temperature and apply derating factors leads to dangerously undersized wiring.

- Ignoring Conductor Count: Using Table 310.15(B)(16) for more than three conductors without applying adjustment factors can result in overheating.

- Misinterpreting Insulation Type: Using the wrong row for the insulation type can lead to incorrect ampacity values.

Beyond the Basics: Advanced Considerations

While Table 310.15(B)(16) provides a foundational framework, other factors may influence ampacity. Ongoing research suggests that even humidity could play a role, though its precise effects are still being investigated. Some experts also debate the effectiveness of certain derating methods, suggesting further refinements are possible. Additionally, emerging conductor technologies might alter future ampacity guidelines. When in doubt, consult a qualified electrician. They can navigate the complexities of the NEC and ensure your wiring is safe and compliant.

Practical Applications and Examples

Let’s illustrate the table’s application with a simple example: You’re installing a 120V circuit for a 15A receptacle using THHN-insulated copper wire in an ambient temperature of 30°C. Table 310.15(B)(16) likely shows an ampacity of 20A for 14 AWG copper THHN at 30°C. Since 15A is less than 20A, 14 AWG wire is suitable for this application.

Staying Current with the Code

Electrical codes evolve. New technologies and ongoing research continually refine our understanding of electrical safety. Always consult the latest edition of the NEC and related standards for the most current information.

To learn more about the licensing of cosmetologists, visit the Tennessee Board of Cosmetology website. Additionally, if you are interested in the regulations and laws governing cosmetology in Tennessee, you can find more information on the Tennessee State Board of Cosmetology website.

Why Section 310 of the NEC Matters

Section 310 of the NEC isn’t just about wires; it’s the bedrock of safe and reliable electrical installations. It sets the standards for conductors, ensuring they’re sized, insulated, and installed correctly. This section covers everything from ampacity and insulation types to conductor markings and permitted uses. Understanding Section 310 is crucial for preventing overheating, fires, and other electrical hazards.

Deeper Dive into Table 310.15(b)(16)

Table 310.15(b)(16) is your go-to resource for determining the safe current-carrying capacity of insulated conductors rated up to 2,000V. It factors in conductor material, insulation type, and ambient temperature. Using this table correctly ensures your wiring can handle the electrical load without overheating, a critical safety consideration. Ongoing research and evolving technologies may influence future iterations of this table, so staying updated with the latest NEC is vital.

- Unlock Water’s Symbolism: A Cross-Cultural Exploration - April 20, 2025

- Identify Black and White Snakes: Venomous or Harmless? - April 20, 2025

- Unlocking Potential: Origins High School’s NYC Story - April 20, 2025