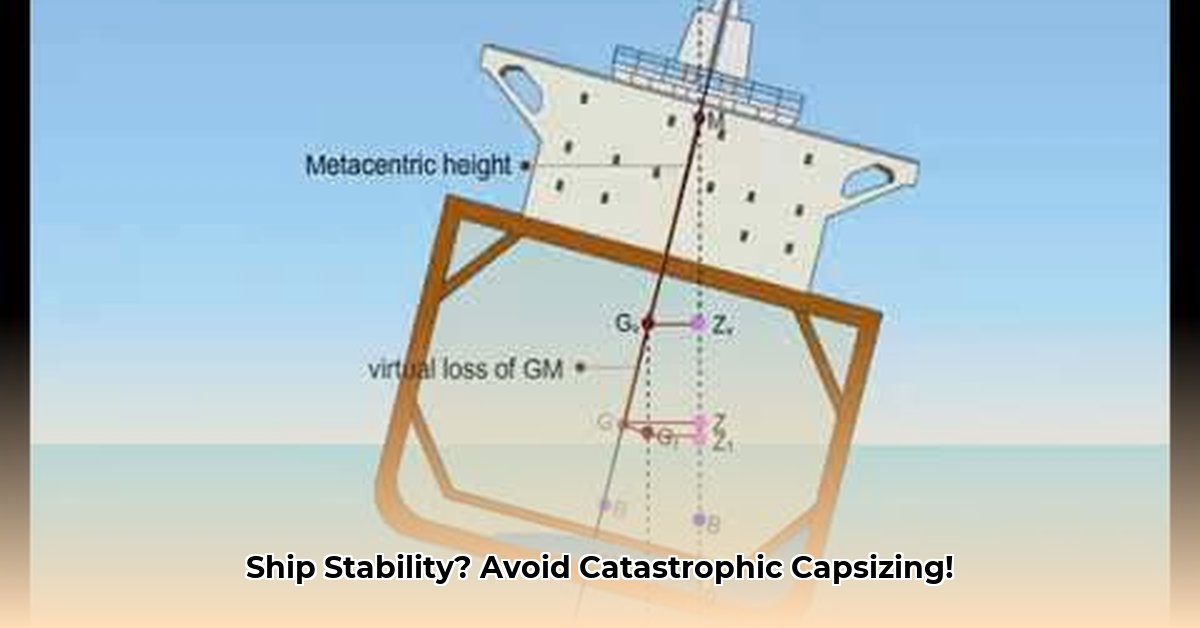

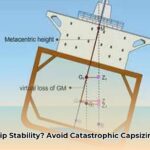

Understanding the Free Surface Effect (FSE)

The free surface effect (FSE) poses a significant challenge to ship stability. It occurs when liquids in partially filled tanks, like ballast or cargo tanks, slosh back and forth as the ship moves. This dynamic shift in liquid weight can compromise the vessel’s stability, potentially leading to hazardous situations, including capsizing. The size of the tank and the volume of liquid within directly influence the severity of the FSE. Larger tanks with greater volumes of liquid allow for more substantial shifts in weight, amplifying the destabilizing effect.

The Physics of FSE: Gravity vs. Inertia

The FSE arises from the fundamental principles of physics—the interplay between gravity and inertia. When a ship rolls, pitches, or yaws, the liquid inside its tanks doesn’t instantly mirror the vessel’s movement due to inertia. This delayed reaction creates a shift in the ship’s center of gravity, reducing its stability. The larger the exposed liquid surface area (the free surface), the greater the potential for this destabilizing shift. This deceptively simple principle has far-reaching implications for ship design and operation.

Real-World Consequences of FSE

Ignoring FSE can have devastating consequences. A seemingly minor list can become amplified, making the ship increasingly vulnerable to capsizing, especially in challenging weather conditions. Violent sloshing can damage cargo, compromise the ship’s structural integrity, and endanger the crew. Recognizing the potential severity of FSE underscores the importance of effective mitigation strategies.

Mitigating the Free Surface Effect: A Multi-Layered Approach

Mitigating FSE requires a comprehensive approach encompassing design modifications, operational procedures, and advanced technologies. Implementing these strategies significantly enhances safety, protecting both crew and cargo.

1. Compartmentalization: Limiting Liquid Movement

Dividing large tanks into smaller, interconnected compartments is a fundamental strategy for reducing FSE. This compartmentalization restricts the movement of the liquid, effectively minimizing the free surface area and its destabilizing influence. The effectiveness of compartmentalization depends on the specific design and number of compartments. A greater number of smaller compartments generally offers greater control over liquid movement and enhanced stability.

2. Pocketing: Creating Internal Barriers

Pocketing involves constructing small, enclosed spaces or “pockets” within larger tanks. These internal barriers further constrain the movement of the liquid, offering an even more refined level of control compared to compartmentalization alone. Pocketing is particularly effective in irregular-shaped tanks or when dealing with liquids prone to violent sloshing.

3. Baffle Systems: Dampening Internal Waves

Baffles are internal partitions strategically placed within tanks to disrupt liquid flow and mitigate sloshing. They act as internal breakwaters, reducing the momentum of the liquid and minimizing its impact on the ship’s stability. Effective baffle design requires careful consideration of the tank’s dimensions, the liquid’s properties (density, viscosity), and the anticipated sea conditions. Advanced computational fluid dynamics (CFD) modeling often plays a crucial role in optimizing baffle design.

4. Strategic Loading Procedures: Maintaining Equilibrium

Precise cargo loading procedures are paramount. Evenly distributing the liquid cargo across multiple tanks minimizes the risk of uneven weight distribution and the resulting instability. Uneven loading can exacerbate FSE, leading to excessive listing or heeling. Modern load planning software and real-time monitoring systems contribute to achieving optimal weight distribution.

5. Real-Time Monitoring: Enhancing Situational Awareness

Advanced monitoring systems provide real-time data on tank levels, liquid movement, and the ship’s overall stability. This continuous flow of information empowers the crew to proactively manage ballast and cargo, making informed decisions to maintain equilibrium and counteract potential FSE issues. These systems also contribute to early detection of leaks or other anomalies that could compromise stability.

Regulatory Compliance and Advanced Considerations

International maritime regulations, such as the SOLAS Convention, provide crucial guidelines for managing FSE. Compliance with these regulations is essential not only for legal reasons but also for ensuring the safety of life at sea and protecting the marine environment. Understanding the nuanced interplay of factors influencing FSE, including fluid properties, tank shape, and ship movements, is fundamental to developing effective mitigation strategies.

Advanced Mitigation Techniques: Leveraging Technology

Cutting-edge technologies, such as computational fluid dynamics (CFD) modeling, offer powerful tools for predicting and mitigating FSE. CFD simulations provide detailed insights into liquid behavior within tanks under a wide range of conditions, allowing for optimized tank design, baffle placement, and operational procedures. This advanced modeling capability significantly enhances the accuracy and effectiveness of FSE mitigation strategies.

Conclusion

The free surface effect presents a formidable challenge to ship stability, but it is a challenge that can be effectively addressed through diligent design, operational best practices, and the application of advanced technologies. Continuous vigilance, adherence to regulations, and the integration of real-time monitoring systems are crucial for safe and efficient ship operations. By embracing a proactive and comprehensive approach to FSE mitigation, the maritime industry can significantly enhance safety at sea and protect valuable assets.

- Amazing March Fun Facts: Unveiling History & Celebrations - April 15, 2025

- Master how to write height: A complete guide - April 15, 2025

- How High Are Your Standards Test: Find Your Perfect Match Now - April 15, 2025