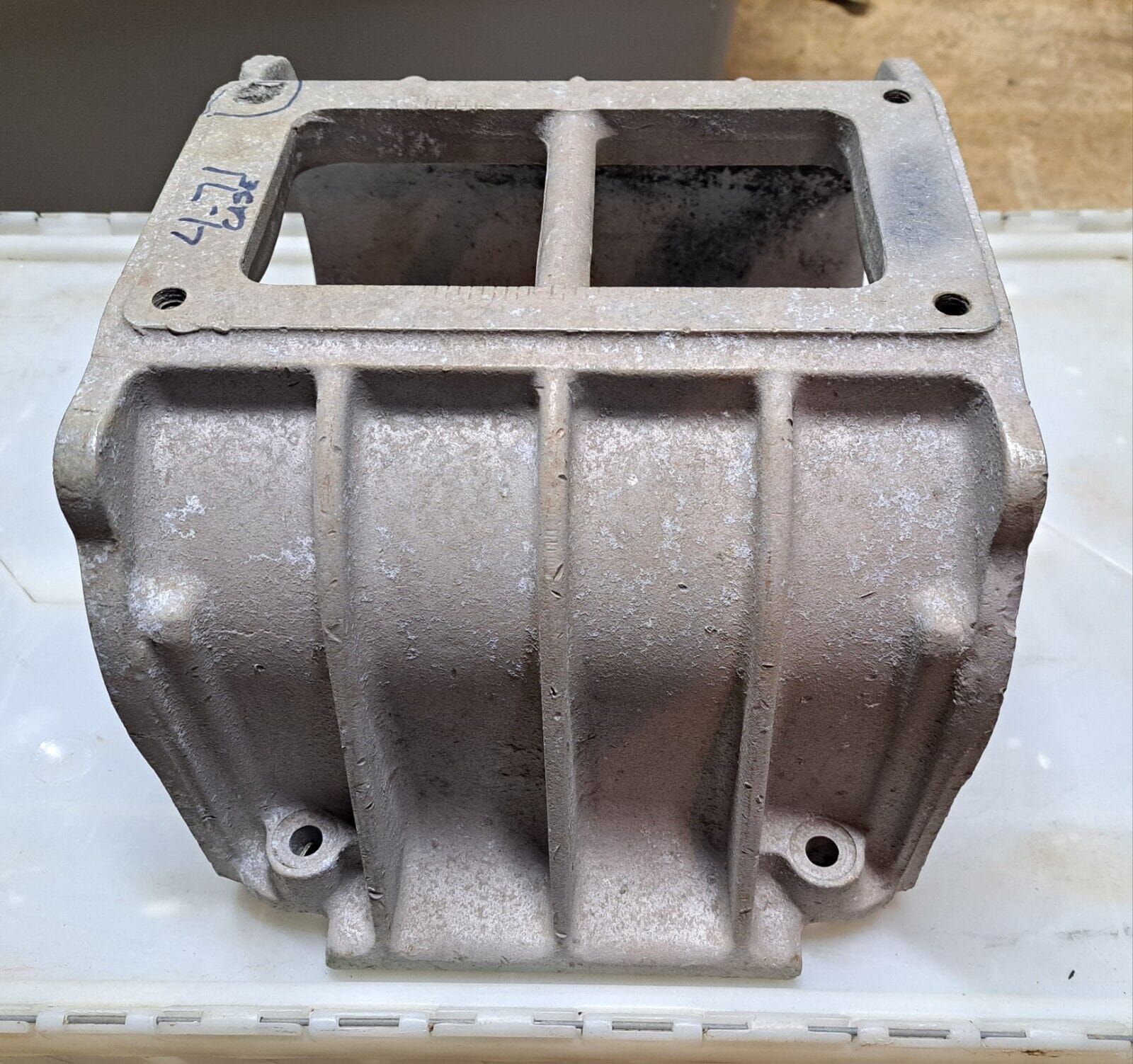

That unmistakable whine echoing from a muscle car or hot rod? It’s likely the distinct sound of a Roots blower. While often referred to as a supercharger, the Roots blower’s operation is subtly different. This deep dive will explore how Roots blowers work, their unique characteristics, advantages, disadvantages, and diverse applications, from dragsters to diesel trucks. We’ll also clarify the “blower vs. supercharger” distinction, comparing Roots blowers to other forced induction methods like turbochargers and other supercharger types. Prepare to uncover the secrets behind this iconic technology.

How Roots Blowers Boost Your Engine

Imagine two figure-eights spinning rapidly within an oval housing. These are the rotors, the heart of a Roots blower. Unlike other superchargers that compress air internally, Roots blowers function as an air pump, scooping and shoving air into the engine. This constant airflow creates positive pressure in the intake manifold, delivering that instantaneous boost Roots blowers are famous for. The compression actually occurs when this increased volume of air encounters the closed intake valves of the engine. While technically a type of supercharger, the Roots blower’s method of moving air rather than compressing it internally is a key distinction.

Instant Power: The Roots Blower Advantage

Roots blowers offer immediate power delivery. No lag, no waiting—pure, instant gratification. This makes them exceptional for applications requiring low-end torque, such as towing or quick acceleration. [https://www.lolaapp.com/rototillers-for-rent] However, their efficiency peaks around a 2:1 pressure ratio (doubling intake pressure), where they achieve roughly 70% efficiency. Pushing beyond this ratio can decrease efficiency due to air leakage around the rotors. This characteristic is similar to trying to contain water in cupped hands; increased pressure can lead to spillage.

Where Roots Blowers Reign

Roots blowers are versatile, appearing in various applications. They power classic American muscle cars, enhance diesel truck performance, and even propel Top Fuel dragsters. Their straightforward design and robust construction ensure reliability across diverse conditions. From hauling heavy loads with [rototillers-for-rent] to achieving rapid acceleration, their consistent low-end torque makes them a popular choice.

Weighing the Pros and Cons of Roots Blowers

Advantages:

- Simplicity and Durability: Their straightforward mechanics and sturdy build contribute to easier maintenance and extended lifespan.

- Instant Boost: Power is available the moment you accelerate, creating a thrilling driving experience.

- Low-End Power: Roots blowers excel at delivering substantial power at lower engine speeds.

- Positive Pressure: They consistently deliver positive intake manifold pressure, ensuring a steady air supply to the engine.

Disadvantages:

- High-Pressure Efficiency: Efficiency tends to decline as boost pressure increases.

- The Whine: The distinctive supercharger whine is a matter of personal preference; some love it, others don’t.

- Heat Generation: Compressing air generates heat, and Roots blowers can produce a considerable amount. This often necessitates the use of intercoolers to cool the compressed air.

Roots Blowers vs. The Competition

Roots vs. Centrifugal Superchargers:

Centrifugal superchargers gradually build boost with increasing engine speed. While they can achieve higher efficiency at high RPMs, they lack the instant low-end power of Roots blowers. Ongoing research explores optimizing impeller designs in centrifugal superchargers for enhanced efficiency. Some experts believe centrifugal superchargers are best suited for applications where peak horsepower is desired.

Roots vs. Twin-Screw Superchargers:

Twin-screw superchargers compress air internally, leading to higher efficiency and quieter operation. However, this increased complexity often translates to higher manufacturing costs and potentially more involved maintenance. Twin-screw designs offer a balance of performance across a wider RPM range, excelling in both low-end torque and high-RPM efficiency.

Roots vs. Turbochargers:

Turbochargers utilize exhaust gases to drive a turbine, which powers a compressor. This offers greater potential efficiency but often results in “turbo lag,” a delay in boost delivery. This is a stark contrast to the immediate boost of a Roots blower. Research continues to address turbo lag, although it remains a challenge.

Roots Blower Technical Details

Roots blowers are typically driven by a belt or gears connected to the engine’s crankshaft. A bypass valve regulates boost pressure, preventing overboosting, and intercoolers cool the compressed air for increased density and power. The signature whine, the sound of air being forcefully delivered to the engine, is a defining characteristic.

The Future of Roots Superchargers

While the fundamental design has remained consistent for over a century, ongoing development explores new materials, coatings, and rotor profiles to enhance performance. Lighter designs, improved high-pressure efficiency, and integration with hybrid power systems are potential future advancements, suggesting an exciting future for this technology.

Roots Blower: Blower or Supercharger?

While the terms are often used interchangeably, a Roots blower is a type of positive displacement supercharger. The distinction lies in how it boosts the engine. Roots blowers displace air, forcing it into the engine where compression occurs against the closed intake valves. This contrasts with other superchargers that compress air internally.

Choosing the Right Forced Induction: Roots and Beyond

Ultimately, the “best” forced induction system depends on your priorities. Roots blowers excel in applications demanding low-end torque, but their high-RPM efficiency may be less ideal. Here’s a comparison table:

| Feature | Roots | Twin-Screw | Centrifugal | Turbocharger |

|---|---|---|---|---|

| Internal Compression | No | Yes | No | Yes |

| Boost Delivery | Instant, low RPM | Linear | High RPM | Lagging, then high RPM |

| Efficiency | Lower, high RPM | Higher | Higher, high RPM | Highest (potential) |

| Complexity | Simpler | More Complex | Moderate | Most complex |

| Cost | Generally Lower | Generally Higher | Moderate | Moderate to high |

| Noise | Distinctive “whine” | Quieter | Moderate whine/whirl | Whooshing/whistling |

| Ideal Application | Trucks, Muscle Cars | General performance | Sports cars, track use | All-around performance, fuel efficiency |

This information provides context for exploring rolled homogeneous armor [https://www.lolaapp.com/rolled-homogeneous-armor] and its protective applications. Each forced induction method has strengths and weaknesses, catering to different needs and driving styles.