The Sustainable Story of Sandstone: From Quarry to Construction

Sandstone, a material echoing ancient castles and timeless structures, faces scrutiny in our eco-conscious era. Is it truly sustainable? The answer lies in responsible sourcing, efficient processing, and a comprehensive lifecycle perspective. Sandstone’s appeal extends beyond its undeniable beauty—rich colors, unique textures, and subtle variations. Its strength and durability allow structures to endure for centuries, showcasing resilience and, surprisingly, sustainability. This longevity minimizes the need for frequent replacements, reducing long-term environmental impact. Responsible quarrying is paramount for ethical extraction. This involves minimizing waste rock, carefully selecting quarry sites to limit ecological disruption, and prioritizing worker safety and fair labor practices. Transparency is crucial, tracing the stone’s origin, understanding its extraction’s environmental impact, and ensuring benefits for local communities.

Natural Sandstone: Balancing Beauty and Environmental Responsibility

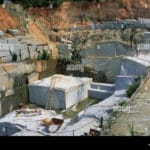

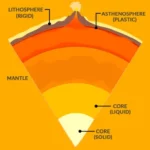

A holistic assessment reveals the complexities of sandstone’s environmental footprint. Extracting, transporting, and processing inevitably have consequences. Quarrying can disrupt ecosystems, transportation consumes fuel and emits pollutants, and processing requires energy and generates waste. A comprehensive Lifecycle Assessment (LCA) provides a complete picture, examining every stage from quarry to disposal or recycling. This assessment is essential for determining true eco-friendliness. Responsible sourcing is the foundation of sustainable practices. Minimizing environmental impact through efficient logistics, utilizing less fuel-intensive transport, is key. Innovative solutions like partnering with facilities closer to quarries or exploring alternative transportation methods could be transformative. Processing and production methods also offer opportunities. Minimizing waste and energy use through water reuse, improved energy efficiency, and renewable energy sources generates long-term benefits.

Sandstone’s Place in Sustainable Construction: A Comparative Analysis

Sandstone holds its own against other building materials. Concrete, for example, carries a high carbon footprint due to the high temperatures required for production. While recycled materials offer greener alternatives, they may not possess the same aesthetic or structural properties. Sandstone’s longevity is a significant advantage—its long lifespan potentially translates to a smaller environmental impact compared to shorter-lived materials. The future of sustainable sandstone rests on transparency, innovation, and collaboration. Companies must disclose their environmental impact through comprehensive sustainability reports detailing efforts in responsible sourcing, energy-efficient processing, and waste reduction. Consumers, armed with this information, can make informed choices. Industry certifications and stringent regulations can further incentivize responsible practices. This collective approach is crucial for the sustainable use of this beautiful material.

Assessing Sandstone’s Impact: A Lifecycle Perspective

How does natural sandstone compare to manufactured alternatives? A full LCA is critical, encompassing raw material sourcing, transportation, and end-of-life disposal. Natural sandstone’s journey begins with energy-intensive extraction, cutting, and transportation, contributing to its carbon footprint. Manufactured stone often utilizes recycled materials and less energy-intensive processes, although the manufacturing itself can generate pollution or require significant energy. A comprehensive LCA considers all stages: raw material extraction, processing, transportation, installation, and end-of-life consequences. Geographical factors, including access to renewable energy, quarry proximity, and transportation infrastructure, also influence the overall impact. Transparent LCA data empowers consumers to make informed decisions.

Sandstone in High-Rise Construction: Reaching for Sustainability

In high-rise construction, sandstone presents a sustainable alternative to traditional materials, offering a lower embodied carbon footprint and inherent durability. Sustainable sourcing is paramount, encompassing responsible quarrying, waste minimization, water recycling, and land restoration. Optimized transportation and efficient processing further minimize environmental impact. Sandstone’s strength, durability, thermal mass, and aesthetic versatility are ideal for high-rise projects. However, geographical availability, supply chain transparency, and thorough LCAs require careful consideration. Innovation plays a crucial role: 3D-printed facades and photocatalytic coatings can further enhance sustainability.

Coastal Construction with Sandstone: Navigating the Challenges

Coastal environments demand materials that withstand salt spray, wind, and temperature fluctuations. Natural sandstone offers durability, but careful consideration of its porosity and permeability is essential. Selecting the right type of sandstone, with appropriate durability and aesthetic qualities, is crucial. Sustainable sourcing through responsible quarrying and ethical labor practices minimizes environmental disruption. Natural sandstone is versatile in coastal projects, suitable for wall cladding, paving, decorative elements, and retaining walls. Proper installation, including sealing and drainage systems, is essential for longevity. A case study featuring a coastal villa constructed with dense, low-porosity sandstone demonstrates the material’s potential in these challenging environments. This example highlights the importance of careful material selection and proper installation techniques for maximizing durability and minimizing environmental impact in coastal construction.

- Mastering Leader in Spanish: The Complete Guide - April 19, 2025

- Uncovering Surprising Parallels: England Size Compared to US States - April 19, 2025

- Old Mexico Map: Border Shifts 1821-1857 - April 19, 2025