Embark on [A Journey through the History of Metalworking], where we explore the evolution of this ancient craft that has shaped human civilization. From the forging of tools in the Stone Age to the precision machining of modern marvels, metalworking has played a pivotal role in our technological advancements and cultural heritage. Join us as we delve into the techniques, innovations, and enduring legacy of metalworking throughout the ages.

Key Takeaways:

- Metalworking has been practiced throughout history across many civilizations.

- It involves shaping, cutting, and joining metals.

- Evolution of techniques, from hand tools to advanced processes, has occurred.

- Modern metalworking includes machining and welding.

- Metalworking has significantly influenced industry, trade, and artistic expression.

History Of Metalworking

Metalworking dates back to prehistoric times, with humans initially using metals like copper and bronze to create tools and weapons. Over time, metalworking techniques evolved, incorporating shaping, cutting, and joining processes that allowed for more intricate and durable creations.

Shaping Techniques:

– Forging: Using heat and hammering to shape metal.

– Rolling: Passing metal through rollers to reduce thickness and increase length.

– Extrusion: Pushing heated metal through a die to create specific shapes.

Cutting Techniques:

– Shearing: Using sharp blades to cut metal in straight lines.

– Sawing: Using a saw to cut curved lines or complex shapes.

– Punching: Using a punch and die to create holes or slots.

Joining Techniques:

– Welding: Using heat or pressure to fuse metal pieces together.

– Soldering: Using a third metal with a lower melting point to join two metal pieces.

– Riveting: Inserting a rivet (a small, cylindrical piece of metal) to connect metal sheets.

With the onset of the Industrial Revolution, metalworking expanded rapidly, leading to the development of new technologies like the steam engine and the automobile. Today, modern metalworking encompasses a wide range of advanced processes, including machining and welding, enabling the production of complex and precise metal components.

Throughout history, metalworking has played a vital role in human civilization, from the creation of everyday tools to the construction of monumental structures. Its evolution has paralleled technological progress, showcasing the ingenuity and adaptability of humankind.

Knowing the history of metal is important if you are a fan of heavy metal music, and would like to learn more about its evolution throughout the years. If you want to know about the history of metal and want to read more about it, you need to do your research and check out books, magazines, blogs, and articles online. Studying the history of metallurgy is also significant as it explores the production of metals such as iron, steel, aluminum, and others.

If music interests you, you may also want to know the history of metal music. It discusses the origins and influences of this genre of music. There are more topics that you can browse online, like the history of Metallica, history of metal documentary, and history of metals timeline. For those who are into horror and are curious about its connection to this genre of music, you may read about the history of metal and horror. Lastly, if you are interested in learning about the history of metal detectors, there are plenty of resources available online to help you learn more about its development and advancements throughout the years.

Middle Ages to Renaissance: Metalworking as an Art Form and Technological Catalyst

Key Points:

- Medieval metalworking flourished under church patronage, with craftsmen gaining recognition.

- Naturalism emerged in the 13th century, as seen in Hugo d’Oignies’ work.

- Wealthy patrons during the Renaissance commissioned elaborate and naturalistic metalwork.

- Islamic metalwork was distinct due to religious restrictions on gold and silver use.

During the Middle Ages to Renaissance period, metalworking evolved significantly as an art form and technological catalyst. Skilled craftsmen transformed metal into intricate creations, shaping history and leaving a lasting legacy.

- Church Patronage:

- In the 12th century, the church became a significant patron of metalworking, commissioning elaborate pieces for religious purposes.

This patronage nurtured the skills of craftsmen, who became renowned for their artistry and innovation.

Naturalism and Detail:

- In the 13th century, naturalism gained prominence in metalwork.

Hugo d’Oignies’ works exemplified this style, incorporating intricate details and realistic human figures.

Wealth and Patronage:

- During the Renaissance, royal courts, aristocrats, and wealthy merchants emerged as patrons of metalworking.

They commissioned elaborate and naturalistic pieces, showcasing their wealth and status.

Islamic Metalwork:

- Islamic metalworkers faced restrictions on using gold and silver due to religious beliefs.

- However, they excelled in creating intricate and highly valued objects using copper, brass, and iron.

Citations:

- Medieval Metalworks and Enamels

- Metalwork, Early and Medieval

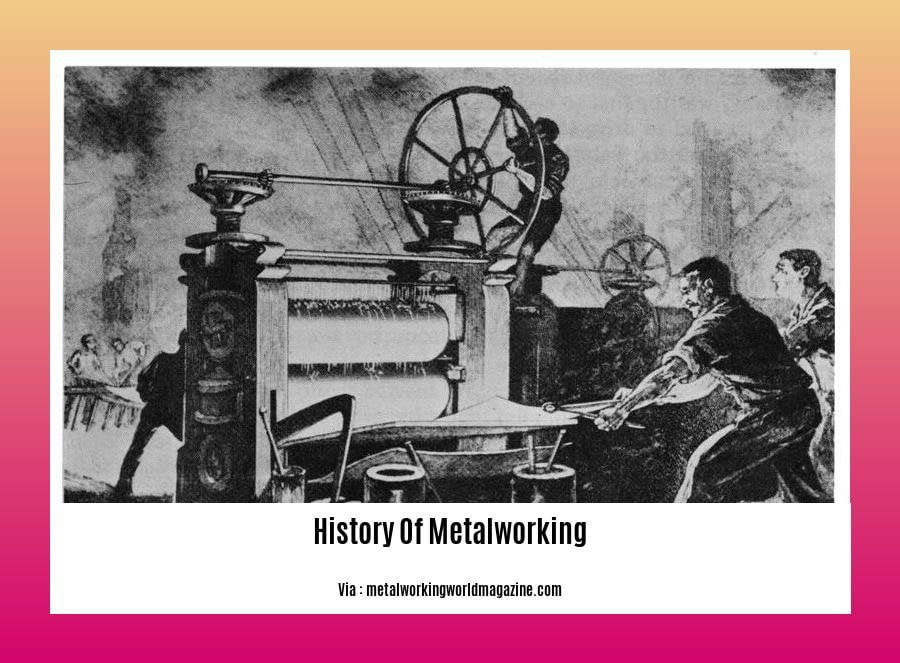

Industrial Revolution: Mass Production and the Birth of Modern Metalworking

Imagine human progress without metalworking – it’s simply unimaginable! From the stunning ancient artifacts to the sleek structures of today, metalworking has been the backbone of human advancement.

The Industrial Revolution marked a turning point in metalworking. In the 1830s and 1840s, mass production techniques emerged, forever changing the metalworking landscape.

Key Takeaways:

- The Industrial Revolution introduced mass production techniques that revolutionized metalworking.

- Mass production enabled the creation of complex metal parts and machinery at scale.

- The steam engine, powered by metal components, fueled the Industrial Revolution.

- Modern metalworking techniques, like machining and welding, have their roots in the innovations of the Industrial Revolution.

Citation:

Modern Era: Advanced Technologies and the Future of Metalworking

The Modern Era of metalworking is characterized by the advent of advanced technologies. These technologies have revolutionized the industry, enabling the production of complex and precise components with increased efficiency and accuracy.

Some of the most important technological developments in the modern era of metalworking include:

- Computer-aided design (CAD) and computer-aided manufacturing (CAM): These technologies allow for the creation of detailed 3D models of metal components, which can then be used to generate toolpaths for automated machining processes.

- CNC (computer numerical control) machining: CNC machines are controlled by computers, which allows for precise and repeatable machining operations.

- Laser cutting and welding: These technologies use lasers to cut and weld metal components, resulting in clean and precise cuts and welds.

- 3D printing: 3D printing allows for the rapid prototyping and production of complex metal components.

These technologies are having a major impact on the future of metalworking. They are enabling the production of lighter, stronger, and more durable metal components, which are used in a wide variety of industries, including aerospace, automotive, medical, and construction.

Key Takeaways:

- Advanced technologies are revolutionizing the metalworking industry.

- CAD/CAM and CNC machining enable precise and repeatable machining operations.

- Laser cutting and welding provide clean and precise cuts and welds.

- 3D printing enables rapid prototyping and production of complex metal components.

- These technologies are having a major impact on the future of metalworking.

Sources:

- Modern Metalworking: Advanced Technologies and the Future

- The Future of Metalworking: Advanced Technologies and Innovations

FAQ

Q1: When did metalworking first emerge in human history?

A1: Metalworking traces its origins back to approximately 8000 BC, with the earliest known use of metals.

Q2: How did the Industrial Revolution transform metalworking practices?

A2: The Industrial Revolution introduced mass production techniques, along with innovations like the Spinning Jenny and steam power, revolutionizing metalworking.

Q3: What are some of the key inventions that have shaped the history of metalworking?

A3: The invention of metal smelting in 3800 BC enabled wider use of metals, while the Industrial Revolution brought about advancements like steam power and mass production techniques.

Q4: What was the significance of medieval metalworking during the Carolingian and Ottonian periods?

A4: During the Carolingian and Ottonian periods, patronage from secular rulers promoted the creation of metalwork, often influenced by religious themes and elaborate decoration.

Q5: How did the use of metals differ between medieval European and Islamic cultures?

A5: In medieval Europe, churches were significant patrons of metalwork, while in Islamic cultures, restrictions on using gold and silver led to a focus on highly valued metal objects.

- Sept 31 Myth: Unveiling Calendar Secrets - March 18, 2025

- How Long & Till December 18, 2025: Accurate Countdown Guide - March 18, 2025

- Discover Japanese Artists: A Complete History - March 18, 2025