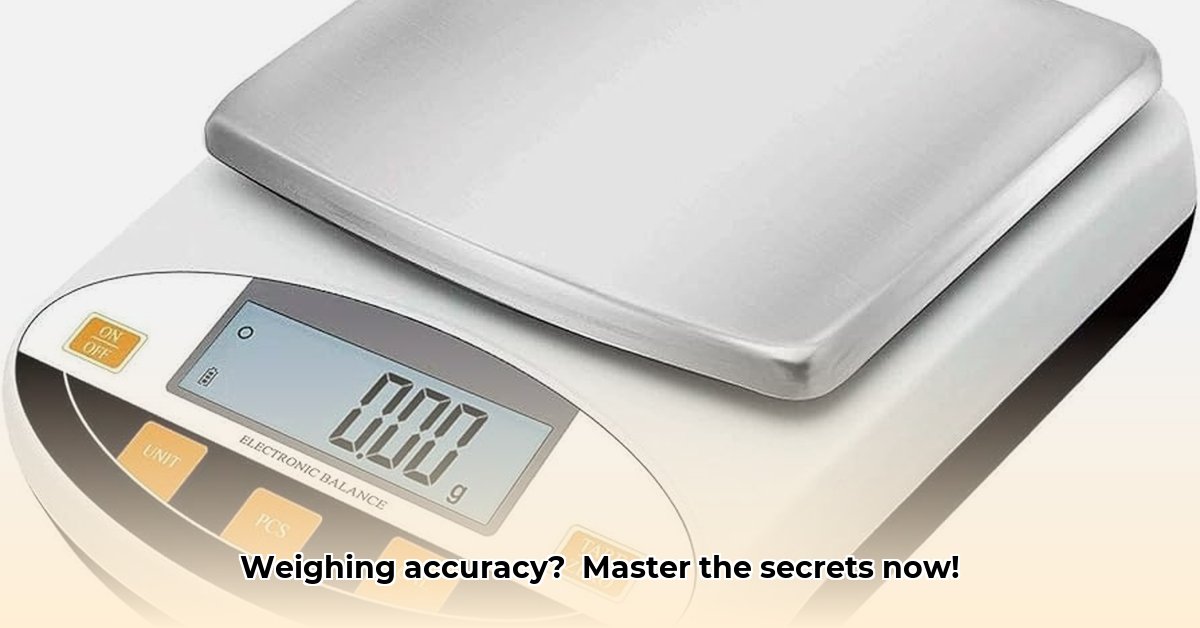

Understanding the Importance of Electronic Balances

Electronic balances have become indispensable tools across various industries, from scientific research and pharmaceutical development to industrial manufacturing and quality control. Their ability to deliver rapid, precise measurements far surpasses traditional mechanical balances. By utilizing advanced load cell technology and strain gauges, these digital scales convert the force exerted by an object’s mass into an electrical signal, providing a highly accurate digital readout. This guide delves into the intricacies of electronic balances, encompassing their functionality, calibration procedures, best practices, and advanced applications.

Calibration: The Cornerstone of Accurate Measurement

Maintaining the accuracy of your electronic balance hinges on regular calibration. Think of it as tuning a musical instrument; without regular adjustments, even minor discrepancies can accumulate, leading to significant inaccuracies that compromise research findings, production quality, or even safety protocols. Calibration entails using certified reference weights to verify and adjust the balance’s readings, ensuring consistent and reliable measurements. The frequency of calibration depends on factors such as usage, environmental conditions, and industry regulations. Always refer to your balance’s manual for specific calibration instructions and recommended intervals.

Selecting the Right Electronic Balance: A Critical Decision

Electronic balances come in a diverse range of models, each designed with specific capacities, readabilities, and features. Choosing the appropriate balance is paramount for optimizing your workflow and budget. Consider the following factors when making your selection:

- Capacity: The maximum weight the balance can accurately measure.

- Readability: The smallest weight increment the balance can display.

- Features: Specialized functions such as parts counting, percentage weighing, density determination, data logging, and connectivity options.

Understanding your specific application requirements will guide you toward selecting the most suitable and cost-effective balance.

Calibration Procedures: A Detailed Walkthrough

While specific calibration procedures may vary between models, the following general steps apply to most electronic balances:

Preparation: Ensure the balance is placed on a stable, level surface, away from drafts, vibrations, and direct sunlight. Allow the balance to warm up according to the manufacturer’s recommendations. This minimizes temperature-related errors.

Zeroing/Taring: With no load on the weighing pan, press the tare or zero button to establish a baseline reading of zero.

Calibration Weights: Use certified calibration weights that are traceable to national or international standards. Choose weights appropriate for your balance’s capacity and readability.

Placement: Carefully place the calibration weight on the center of the weighing pan, avoiding sudden movements or impacts.

Reading and Adjustment: Compare the displayed weight to the known value of the calibration weight. If a discrepancy exists, consult your balance’s manual for instructions on adjusting the internal calibration settings.

Verification: Repeat the calibration process with different calibration weights, spanning the balance’s weighing range, to ensure accuracy across the entire scale.

Documentation: Meticulously record the calibration date, the weights used, and any adjustments made. This documentation creates an audit trail for traceability and compliance with regulatory requirements.

Beyond Calibration: Best Practices for Enhanced Performance

While calibration is crucial, incorporating these additional practices will further optimize the performance and longevity of your electronic balance:

Environmental Control: Maintain a stable laboratory environment by minimizing temperature fluctuations, air currents, and vibrations. Consider using an anti-static device to mitigate the effects of static electricity.

Proper Handling: Avoid overloading the balance. Gently place items on the weighing pan to prevent damage to the load cell.

Regular Cleaning: Keep the balance clean by following the manufacturer’s cleaning instructions. Dust, debris, and chemical spills can significantly impact the accuracy of measurements.

Routine Maintenance: Schedule regular preventative maintenance checks with a qualified technician to ensure optimal performance and identify potential issues before they escalate.

Regulatory Compliance and Data Integrity

In regulated industries such as pharmaceuticals and food processing, strict adherence to weighing procedures and ensuring data integrity are paramount. Implementing a Laboratory Information Management System (LIMS) can significantly assist in managing calibration records, weighing data, and generating audit trails for compliance.

Advanced Applications and Troubleshooting

Modern electronic balances often include advanced features that extend their functionality beyond basic weighing. Explore these capabilities to streamline your workflows:

- Density Determination: Determine the density of solids and liquids with built-in density determination kits.

- Parts Counting: Accurately count large quantities of small, identical items.

- Percentage Weighing: Calculate the percentage difference between a reference weight and a sample weight.

- Data Connectivity: Interface with computers and printers for data logging, analysis, and report generation.

Should you encounter issues with your electronic balance, consider the following troubleshooting tips:

- Inconsistent Readings: Check for environmental factors such as drafts, vibrations, or static electricity. Ensure the balance is level and properly calibrated.

- Drifting Readings: Stabilize the temperature and allow sufficient warm-up time. Verify that the balance is not overloaded.

- Incorrect Weight Readings: Recalibrate the balance. If the problem persists, contact the manufacturer or a qualified service technician.

- Unlock Filipino Culture: A Deep Dive into Traditions and Practices - April 23, 2025

- Unlock Spanish Culture: Insights & Opportunities Now - April 23, 2025

- White Spirit Uses & Substitutes: A Deep Dive for Pros & DIYers - April 23, 2025