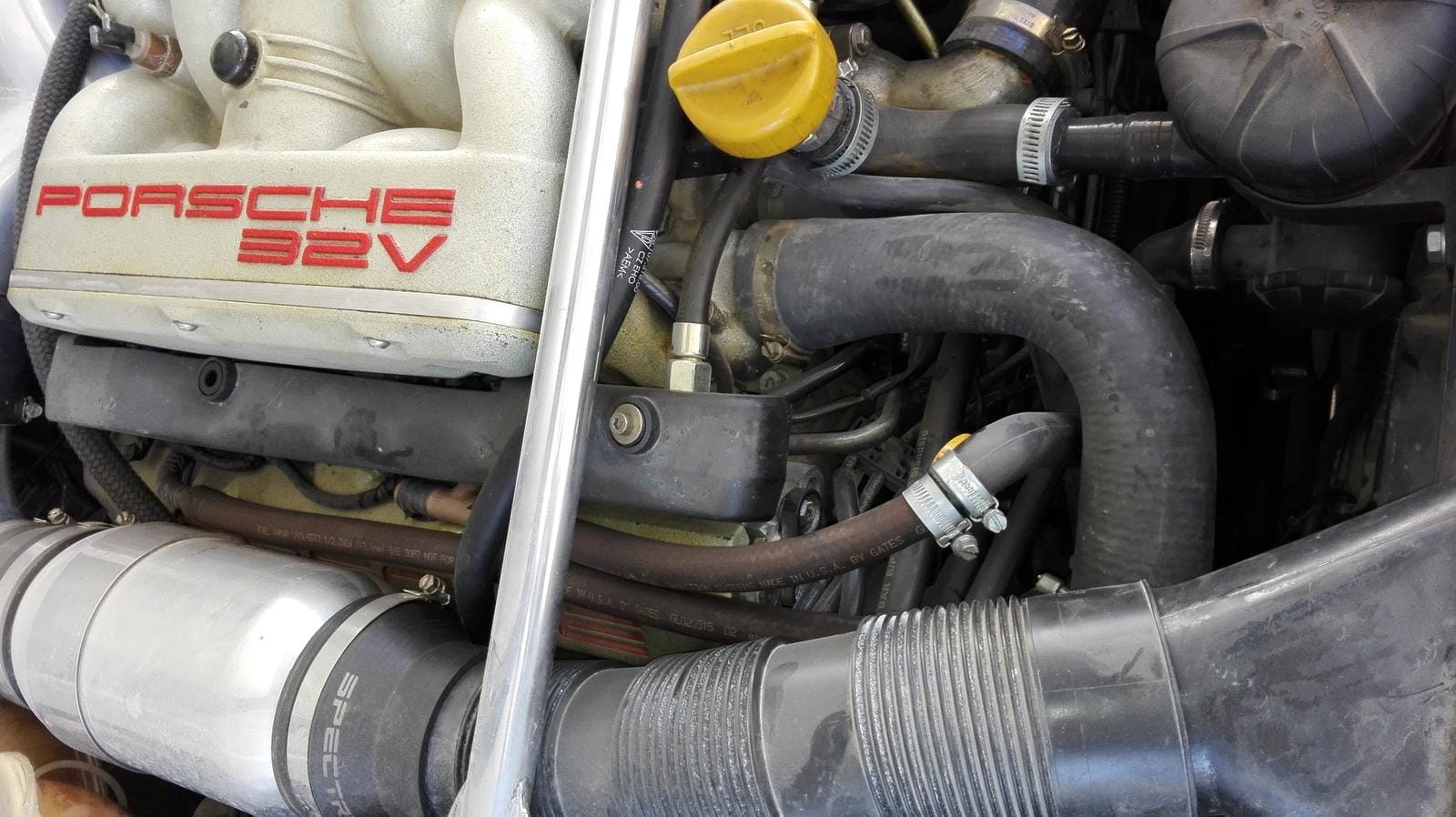

Ever wonder about all the tubes and components under your car’s hood? One crucial, often overlooked system is crankcase ventilation, sometimes called “crankcase breathing.” It’s vital for engine health and performance. This comprehensive guide explains what crankcase breathing is, why it’s important, how to spot problems, and how to maintain it.

What is Crankcase Breathing?

Your engine needs to “breathe” to vent internal pressure and remove unwanted gases. This process, known as crankcase breathing or crankcase ventilation, is essential for smooth engine operation. https://www.lolaapp.com/carterville-il-county

During combustion, some gases and oil vapor (blow-by) escape past the piston rings and into the crankcase. Without ventilation, this pressure buildup can cause oil leaks, damage seals, and reduce engine performance. Crankcase breathing systems provide an escape route for these gases.

Older systems used simple breathers that vented to the atmosphere. Modern vehicles utilize a Positive Crankcase Ventilation (PCV) valve, redirecting blow-by gases back into the intake manifold to be burned, improving efficiency and reducing emissions. Some systems also include an oil separator to remove oil droplets from the gases before they re-enter the intake.

Why is Crankcase Breathing Important?

Crankcase breathing is crucial for several reasons:

- Pressure Regulation: A properly functioning system prevents excessive pressure buildup, protecting seals, gaskets, and other components.

- Contaminant Removal: Blow-by gases contain combustion byproducts, unburned fuel, and moisture that can contaminate oil and corrode engine parts. Crankcase breathing removes these contaminants.

- Performance Optimization: By venting pressure and removing contaminants, crankcase breathing contributes to optimal engine performance and longevity.

How Crankcase Ventilation Works

From Draft Tubes to PCV Valves

Early cars used draft tubes—simple hoses venting blow-by gases directly into the atmosphere. While functional, this method contributed to pollution.

Modern systems employ the PCV valve. This valve regulates the flow of blow-by gases back into the intake manifold, where they are burned during combustion. This reduces emissions and improves fuel efficiency.

Components of the PCV System

The PCV system typically consists of:

- PCV Valve: This valve acts as a one-way door, preventing backfires from reaching the crankcase while allowing gases to flow into the intake manifold.

- Hoses: These connect the crankcase, PCV valve, and intake manifold, acting as the system’s airways.

- Oil Separator (Optional): This component, sometimes integrated into the PCV valve, removes oil from the blow-by gases before they enter the intake.

Recognizing the Symptoms of a Faulty System

A malfunctioning crankcase breathing system can manifest in various ways:

- Rough Idling: Blow-by gases disrupting the air-fuel mixture can cause rough idling and poor acceleration.

- Oil Leaks: Excessive crankcase pressure can force oil past seals and gaskets, resulting in leaks.

- Burning Oil Smell: Escaping blow-by gases can produce a noticeable oil smell.

- Increased Oil Consumption: A faulty PCV valve can allow oil to be drawn into the intake and burned, increasing oil consumption.

- Sludge Buildup: Accumulated blow-by gases can contaminate oil, leading to sludge buildup.

- Check Engine Light: A malfunctioning system can trigger the check engine light. A diagnostic scan can pinpoint the specific trouble code. https://www.lolaapp.com/bruceville-eddy-isd

Sometimes, multiple warning lights, such as the Electronic Power Control (EPC), Traction Control System (TCS), and check engine lights, might illuminate simultaneously, suggesting a crankcase breather problem.

Diagnosing and Maintaining Your System

Diagnosing Problems

If you suspect a problem, start with a visual inspection. Check hoses for cracks, kinks, or blockages and ensure connections are tight. A simple test for the PCV valve involves shaking it—it should rattle. A lack of rattle suggests it might be clogged and needs replacing.

Keeping It Healthy

Regular maintenance prevents many issues. Replace the PCV valve according to your vehicle manufacturer’s recommendations. Inspect and replace hoses as needed. Cleaning system components can prevent sludge buildup.

For high-performance engines, increased stress and blow-by may require specialized solutions like catch cans or high-flow PCV valves.

The Future of Crankcase Breathing

Crankcase breathing technology continues to evolve. Research explores more efficient ways to manage blow-by gases, enhancing engine performance and reducing emissions. Ongoing advancements aim to further refine the PCV system, integrating sensors and electronic controls for optimized performance and reduced environmental impact.

While the future is uncertain, efficient crankcase breathing will remain vital for engine health and performance. By understanding its function and performing regular maintenance, you can contribute to your engine’s longevity and efficient operation. Remember, a little preventative care goes a long way!

- China II Review: Delicious Food & Speedy Service - April 17, 2025

- Understand Virginia’s Flag: History & Debate - April 17, 2025

- Explore Long Island’s Map: Unique Regions & Insights - April 17, 2025