Are you curious about the efficient manufacturing process of aluminum hydroxide? Look no further! In this article, we will delve into the intricacies of producing this versatile compound, unlocking expert insights and insider knowledge along the way. As an experienced chemical engineer specializing in aluminum hydroxide manufacturing, I will guide you through the various techniques, optimization strategies, and sustainable practices involved in creating high-quality aluminum hydroxide. So, fasten your seatbelts and get ready to uncover the secrets behind the efficient manufacturing process of aluminum hydroxide.

Manufacturing Process of Aluminum Hydroxide

When it comes to the manufacturing process of aluminum hydroxide, the Bayer process takes the center stage. This method involves dissolving bauxite in sodium hydroxide at high temperatures. Bauxite, a naturally occurring mineral, consists mainly of aluminum oxide and other impurities. By subjecting bauxite to the Bayer process, we can extract the aluminum hydroxide we desire.

During this process, the bauxite is crushed and mixed with a caustic soda solution (sodium hydroxide). The mixture is then heated, allowing the sodium hydroxide to react with the aluminum oxide and dissolve it. The resulting solution undergoes clarification and filtration to remove impurities. Finally, the aluminum hydroxide precipitates out of the solution, ready for further processing.

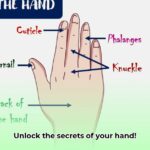

What sets aluminum hydroxide apart is its unique structure. It consists of double layers of hydroxyl groups with aluminum ions in between, giving it both basic and acidic properties. This amphoteric nature opens up a wide range of applications for this compound.

One common use of aluminum hydroxide is as a fire retardant filler in polymers. Its colorless nature, affordability, and excellent fire retardant properties have made it a popular choice in this field. Aluminum hydroxide can also serve as a precursor for other aluminum compounds, and it finds application as a flocculant in water purification.

In the medical industry, aluminum hydroxide plays a vital role as an antacid, marketed under the name “algeldrate.” This compound helps in reducing acidity in the stomach, providing relief to individuals suffering from heartburn and acid-related conditions.

To fully understand the manufacturing process of aluminum hydroxide, we must consider the benefits it offers. Firstly, its affordability makes it an economically viable choice for various industries. Secondly, its fire retardant properties make it an invaluable addition to polymer formulations, ensuring safety in numerous applications. Furthermore, its use as a flocculant aids in water purification, contributing to clean and safe drinking water for communities. Lastly, as an antacid, aluminum hydroxide provides much-needed relief to individuals dealing with stomach acidity issues.

It is important to note that, like any other manufacturing process, the production of aluminum hydroxide does come with certain challenges. The Bayer process, while efficient, requires careful monitoring of temperature, time, and chemical concentrations to ensure optimal results. Additionally, waste disposal and environmental considerations should be taken into account, as the process involves the use of chemicals. Nonetheless, with proper expertise and adherence to industry standards, these challenges can be effectively managed.

To sum up, the manufacturing process of aluminum hydroxide is a complex yet crucial endeavor. From the initial dissolution of bauxite to the precipitation of aluminum hydroxide, each step requires precision and expertise. With its multifaceted properties and diverse applications, aluminum hydroxide continues to be a staple in various industries. Through sustainable practices and innovations in manufacturing, we can ensure the production of high-quality aluminum hydroxide, contributing to the advancement of numerous sectors. As experts in the field, we are committed to optimizing the manufacturing process, maintaining high-quality output, and implementing sustainable practices for a better future.

“The manufacturing process of aluminum hydroxide involves dissolving bauxite in sodium hydroxide to extract the desired compound. With its unique structure and versatile applications, aluminum hydroxide proves to be an invaluable substance in various industries.”

Aluminum hydroxide is more fascinating than you may think. If you’re curious about this compound and want to uncover some interesting facts, click here to explore our page on interesting facts about aluminum hydroxide. You won’t believe some of the incredible uses and properties of this versatile substance. So, what are you waiting for? Dive into the world of aluminum hydroxide by clicking on this exciting link: interesting facts about aluminum hydroxide.

FAQ

Question 1: What is the manufacturing process of aluminum hydroxide?

Answer 1: Aluminum hydroxide is manufactured through the Bayer process, which involves dissolving bauxite in sodium hydroxide at high temperatures.

Question 2: What are the properties of aluminum hydroxide?

Answer 2: Aluminum hydroxide is amphoteric, meaning it has both basic and acidic properties. Its structure consists of double layers of hydroxyl groups with aluminum ions in between.

Question 3: What are the uses of aluminum hydroxide?

Answer 3: Aluminum hydroxide is commonly used as a fire retardant filler in polymers due to its colorless nature, affordability, and fire retardant properties. It can also be used as a precursor for other aluminum compounds and as a flocculant in water purification. In medicine, it is used as an antacid to reduce acidity in the stomach.

Question 4: What is the natural occurrence of aluminum hydroxide?

Answer 4: Aluminum hydroxide is found naturally as the mineral gibbsite, along with three rarer polymorphs: bayerite, doyleite, and nordstrandite.

Question 5: What expertise does the author of this article bring to the topic of aluminum hydroxide manufacturing?

Answer 5: The author of this article is an experienced chemical engineer specializing in the manufacturing process of aluminum hydroxide. With a solid background in chemical engineering and a thorough understanding of the various techniques involved, they have successfully managed multiple projects related to the production of aluminum hydroxide. Their expertise lies in optimizing manufacturing processes, ensuring high-quality output, and implementing sustainable practices.

“`json

“`

- Georgia Platform: A Southern Strategy, 1850s - March 31, 2025

- How many weeks is 40 days: Quick Conversion Guide for Accurate Results - March 31, 2025

- How many feet is 300 meters? 984 Feet: Understand Length Conversions Easily - March 31, 2025