Concerned about potential contaminants lurking in your drinking water? Backflow, the unwanted reversal of contaminated water into your clean water pipes, is a serious threat. Anti-siphon valves act as vigilant guardians, protecting your water supply. This comprehensive guide explores everything you need to know about these essential plumbing components, from their function and various types to installation, maintenance, and troubleshooting.

Decoding Anti-Siphon Valves

What is Backflow and Why Should You Care?

Your home’s plumbing system is a network of pipes delivering fresh water to your taps. However, events like a fire hydrant’s use, a water main break, or even high demand during peak hours can cause pressure drops, leading to backflow. This means contaminated water, potentially containing fertilizers, pesticides, or even sewage, can be drawn backwards into your clean water pipes. Anti-siphon valves prevent this by acting as one-way doors, allowing water to flow into your home but blocking anything trying to sneak back in.

Types of Backflow Prevention Devices

Several types of anti-siphon devices exist, each designed for a specific purpose:

- Bottle Traps: These simple, curved pipes with a water reservoir are found under sinks and tubs, blocking sewer gases and contaminated water.

- Air Admittance Valves (AAVs): These valves allow air into the pipes when pressure drops, preventing the vacuum that can cause back-siphonage. They offer a modern alternative to complex venting systems.

- Specialized Backflow Preventers: For complex systems like irrigation, boats, and fuel tanks, specialized preventers offer tailored protection. In irrigation, they stop fertilizers and pesticides from reaching drinking water; on boats, they prevent saltwater intrusion; and in fuel tanks, they minimize spills.

- Check Valves/Non-Return Valves: While these valves prevent some backflow by allowing flow in only one direction, they might not protect against back-siphonage caused by vacuum pressure.

Where Backflow Preventers Are Essential

Backflow preventers play a crucial role in various applications:

- Plumbing Fixtures: They protect your water supply every time you use a sink, shower, or tub.

- Irrigation Systems: Essential for preventing contamination by fertilizers, pesticides, and other landscaping chemicals.

- Marine Applications: Keep saltwater out of freshwater systems on boats, preventing corrosion and ensuring smooth operation.

- Fuel Tanks: Help prevent spills and protect the environment.

How Backflow Preventers Work

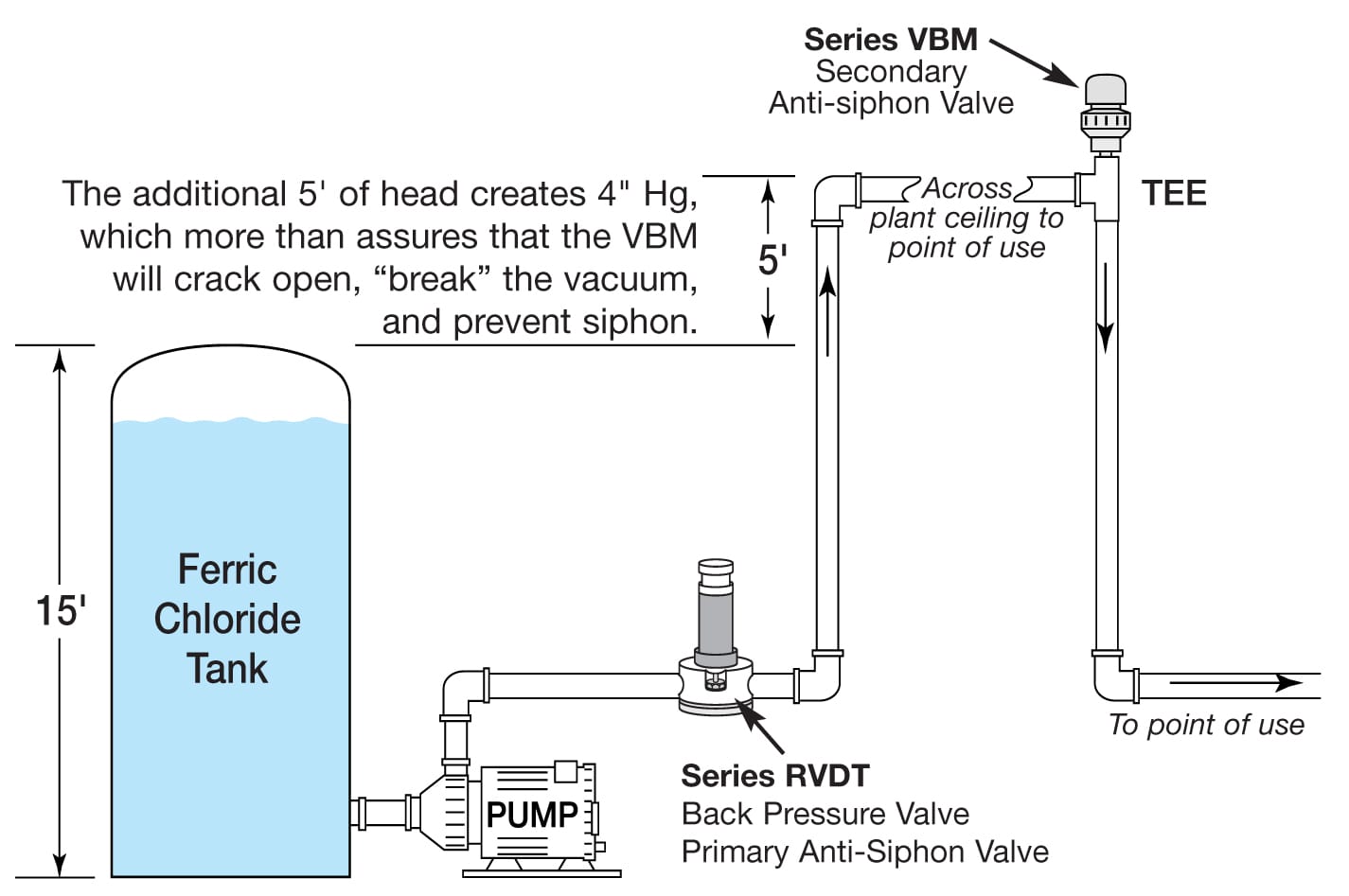

Back-siphonage occurs when a pressure drop creates suction, drawing contaminated water back into the pipes. Backflow preventers use various mechanisms to disrupt this reverse flow. AAVs allow air into the pipes, equalizing pressure. Others use gravity or mechanical barriers, like check valves, to create a physical obstruction. The specific mechanism depends on the device and its application.

Installation and Maintenance

Proper installation is critical for effectiveness. Always follow the manufacturer’s instructions. Regular inspection and maintenance are also essential. Watch for leaks or difficulty flushing appliances, as these may indicate a problem.

| Backflow Preventer Type | Application | Material | Typical Sizes |

|---|---|---|---|

| Bottle Trap | Sinks, tubs | Plastic, brass | 32mm, 40mm |

| Air Admittance Valve (AAV) | Plumbing vents | Plastic | 40mm, 50mm |

| Irrigation Backflow Preventer | Sprinkler systems | Plastic, metal | Varies |

| Marine Backflow Preventer | Boats | Brass, bronze, stainless steel | Varies |

What Does an Anti-Siphon Valve Do?

Anti-siphon valves are critical plumbing components that protect your clean water from contamination. They act as one-way gates, allowing water to flow in only one direction and preventing backflow. This safeguards your family’s health by maintaining water purity.

Several mechanisms achieve this one-way flow. Some use a mechanical “swinging door” that opens with forward pressure but closes if pressure reverses. Others create an air gap, breaking the water flow and preventing backflow. The specific mechanism depends on the valve and its purpose.

A Variety of Valves for Various Applications

Different plumbing situations require different anti-siphon valves:

- Anti-Siphon Faucets: These faucets offer built-in protection, typically used outdoors where garden hoses are connected, preventing contaminants from entering your home’s water supply.

- Hose Bib Vacuum Breakers: Attached directly to outdoor faucets, these devices prevent backflow during pressure drops. A small air vent opens when pressure decreases, preventing a vacuum.

- Atmospheric Vacuum Breakers (AVBs): Commonly used on irrigation systems and toilets, AVBs use an air inlet to prevent backflow.

- Pressure Vacuum Breakers (PVBs): More complex devices used in high-hazard applications, such as chemical tanks, combining check valves and air inlets for greater protection.

- Double Check Valve Assemblies (DCVAs): Using two check valves in series, DCVAs offer enhanced protection, typically used in commercial and industrial settings.

- Reduced Pressure Zone (RPZ) Valves: The most robust type, designed for high-hazard situations where backflow poses significant health risks (e.g., lawn care businesses using fertilizers). RPZ valves combine check valves, relief valves, and a reduced pressure zone.

Why Are Anti-Siphon Valves Important?

Anti-siphon valves are crucial for protecting your drinking water from various contaminants:

- Fertilizers and Pesticides: Chemicals used in landscaping can be hazardous if they enter your drinking water.

- Sewage: Backflow from sewage lines can introduce harmful bacteria and viruses.

- Industrial Chemicals: In some cases, backflow can contaminate drinking water with hazardous industrial substances.

Maintaining Your Anti-Siphon Valves

Regular inspection and maintenance are essential. Check for leaks, debris, and proper function:

- Visual Inspection: Look for cracks or leaks.

- Debris Check: Ensure the valve inlet and outlet are clear.

- Function Test: Observe the valve’s movement when turning water on and off. Listen for unusual sounds.

- Professional Inspection: Consult a qualified plumber if you encounter any problems.

| Type of Anti-Siphon Valve | Application | Description |

|---|---|---|

| Anti-Siphon Faucet | Outdoor faucets | Built-in backflow protection |

| Hose Bib Vacuum Breaker | Hose connections | Prevents hose contamination |

| Atmospheric Vacuum Breaker (AVB) | Irrigation systems, toilets | Uses air inlet |

| Pressure Vacuum Breaker (PVB) | High-hazard applications | Check valves and air inlets |

| Double Check Valve Assembly (DCVA) | Commercial/industrial | Two check valves |

| Reduced Pressure Zone (RPZ) Valve | Highest hazard applications | Multiple components |

While our understanding is extensive, ongoing research refines best practices. Stay informed about the latest recommendations for a safe water supply. Discover the innovative waterless urinal and its impact on conservation. Explore the water level at Lake Cachuma, a vital Southern California resource.

Bypassing an Anti-Siphon Valve

Understanding the Need and the Risks

Sometimes, you might need to bypass an anti-siphon valve, like when a gas tank is empty but you have a full gas can. However, these valves are often designed to prevent fuel theft. Before attempting a bypass, be aware of potential legal consequences and safety hazards. Gasoline is highly flammable, and siphoning fuel may be illegal depending on your location.

One bypass method involves accessing the fuel line from the opposite side of the tank, often requiring a specialized fuel line disconnect tool. For stuck hose bibb valves, removing a hidden set screw, possibly by drilling or using a Dremel tool, might be necessary.

For plumbing, using anti-siphon traps on both bath and basin drains is often more cost-effective than a Durgo valve.

Prioritize safety. Spilled fuel is environmentally harmful, and attempting to bypass a fuel tank’s anti-siphon valve carries significant fire risks. Safer alternatives exist. If the valve is faulty, a qualified mechanic can replace it. If you need immediate fuel access, a locksmith or mechanic can often help legally and safely.

Future developments may lead to more sophisticated anti-siphon systems. Ongoing research explores easier access for vehicle owners in emergencies while maintaining theft protection.

Prioritize safety and legality. Consult official guidelines and seek professional advice when needed.

Why Is Water Coming Out of My Anti-Siphon Valve?

A leaking anti-siphon valve isn’t just annoying; it suggests a potential backflow problem, risking contamination of your clean water. Let’s explore common causes and solutions.

The Diaphragm: A Common Culprit

The diaphragm, a flexible rubber piece inside the valve, acts as a one-way gate. Over time, it can wear out, crack, or tear, causing leaks. Debris can also damage it. Replacing a damaged diaphragm is a relatively simple DIY project.

- Turn Off the Water Supply: Always turn off the main water supply before working on plumbing.

- Access the Diaphragm: Remove the bonnet cap (the top part of the valve).

- Inspect the Diaphragm: Check for tears, cracks, or distortions.

- Replace the Diaphragm: Use the correct size and type for your valve model.

- Reassemble the Valve: Ensure proper alignment and tighten the bonnet cap securely without overtightening.

Debris and Mineral Buildup: Another Potential Cause

Debris and mineral buildup can prevent the internal parts, especially the poppet, from sealing correctly, causing leaks. Cleaning can often resolve this:

- Disassemble the Valve: Turn off the water supply and remove the bonnet cap.

- Remove Debris: Gently clean with a soft brush, cotton swab, or toothpick. Avoid abrasive tools.

- Flush the Valve: Run clean water through the valve.

- Reassemble the Valve: Ensure correct placement of all parts.

Installation Issues: A Frequent Overlooked Problem

Incorrect installation, like improper height or connections, can cause leaks. Simply raising the valve higher is not always a solution and requires careful consideration. Consult local plumbing codes and manufacturer’s instructions. If unsure, call a licensed plumber.

Preventing Future Leaks

Regular maintenance is key. Inspect, clean, and winterize your valves to prevent freeze damage.

| Problem | Likely Cause(s) | Solution(s) |

|---|---|---|

| Dripping Water | Worn diaphragm, debris, loose parts | Replace diaphragm, clean valve, tighten connections |

| Continuous Leak | Torn diaphragm, improper installation | Replace diaphragm, consult a plumber |

| Spraying Water | Damaged valve body, high water pressure | Replace valve, check water pressure, consult a plumber |

These are common causes and solutions. If problems persist, consult a qualified plumber. Plumbing can be complex, and other factors might be involved. Remember to prioritize safety and seek professional help when needed.

- Unlock Elemental 2 Secrets: Actionable Insights Now - April 2, 2025

- Lot’s Wife’s Name: Unveiling the Mystery of Sodom’s Fall - April 2, 2025

- Photocell Sensors: A Complete Guide for Selection and Implementation - April 2, 2025