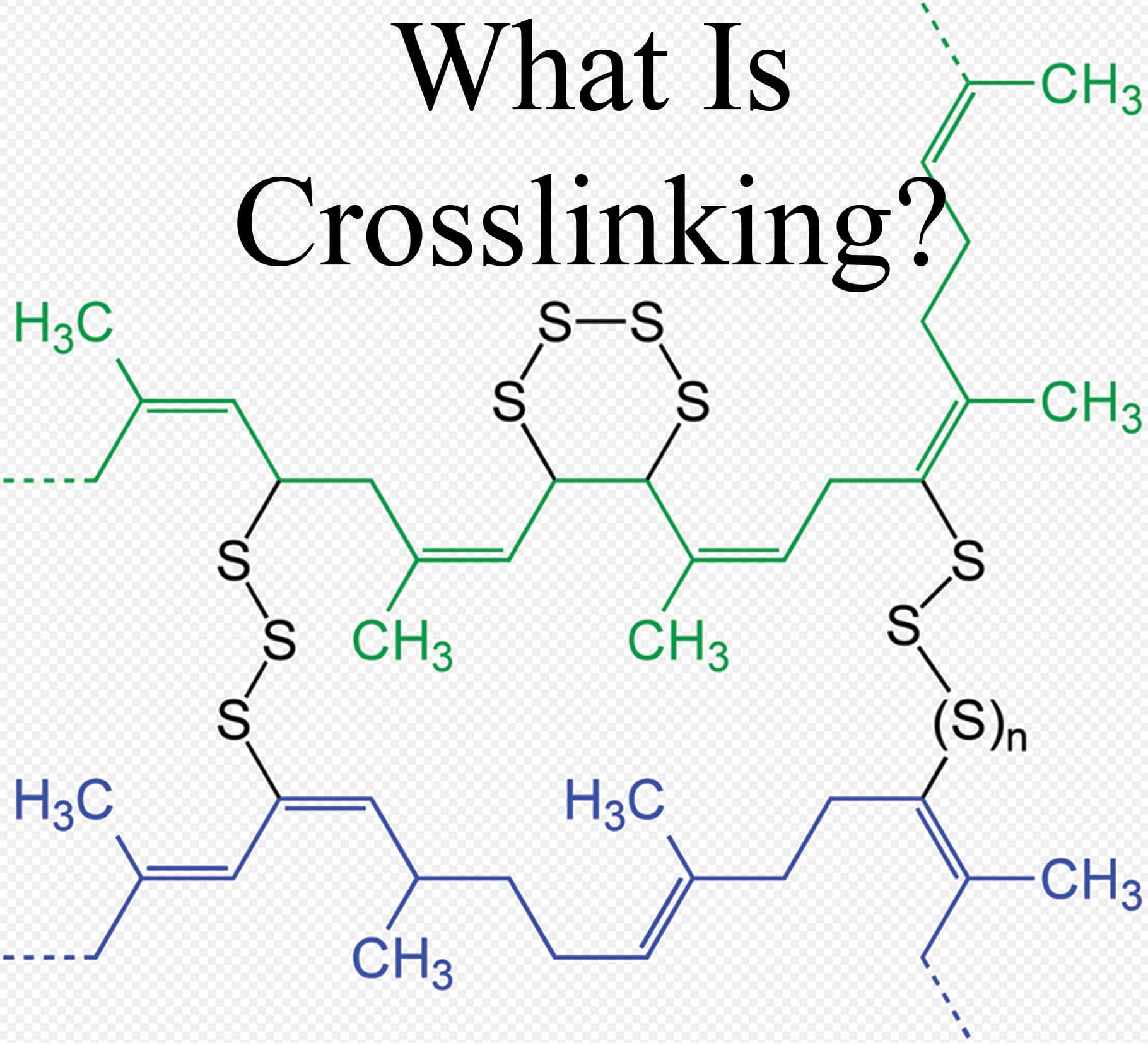

Crosslinking profoundly affects the properties of polymers, transforming them from individual, linear strands into robust, interconnected networks. This process is crucial for creating materials with specific characteristics, from the elasticity of rubber bands to the strength of structural components. This guide explores the methods used to achieve crosslinking, the techniques employed to analyze its extent, and the diverse applications of these modified polymers.

Understanding Crosslinking

Imagine polymers as long, tangled strands of spaghetti. Crosslinking is like strategically placing tiny drops of glue between these strands, creating a more interconnected and robust network. This process dramatically changes the polymers’ properties, making them stronger, tougher, and more resistant to heat. Finding and understanding these crosslinked polymers is crucial in a wide range of applications, from the tires on your car to advanced medical materials. Are you interested in the latest advancements in radiocancerwork? Our point research team is at the forefront of cutting-edge cancer treatments. They are dedicated to finding new and innovative ways to fight this devastating disease. Learn more about their groundbreaking work today!

Key Points:

- Crosslinking involves connecting polymer strands with “glue-like” substances, strengthening and enhancing their robustness.

- This process is essential for tailoring materials for specific applications, impacting strength, flexibility, and interaction with other substances.

Creating Connections: Crosslinking Methods

There are several ways to create these vital crosslinks. Two primary approaches are:

Chemical Crosslinking: This method introduces special molecules, called crosslinking agents, that act as bonding bridges between polymer strands. Think of it like using clips to link multiple strands of spaghetti together. Sulfur, a common crosslinking agent, is crucial in vulcanizing rubber, enhancing its elasticity and durability.

Physical Crosslinking: This approach uses energy, such as radiation or heat, to induce direct bonding between polymer chains. It’s like using a heat source to slightly melt the spaghetti strands together at certain points, creating a more connected structure. This method avoids additional chemicals, which can be advantageous in specific applications.

Investigating the Network: Analyzing Crosslinked Polymers

Once a crosslinked polymer is created, understanding its structure becomes essential. Two key aspects are:

Degree of Crosslinking: This indicates how densely packed the crosslinks are within the polymer network. A higher degree generally leads to a stiffer, more resistant material. Techniques like swelling tests (how much a sponge expands when absorbing water – a less crosslinked polymer will swell more) and dynamic mechanical analysis (DMA), which measures the material’s response to forces, help determine the degree of crosslinking.

Crosslink Characterization: This involves identifying the specific types of crosslinks and their chemical structure. Advanced techniques like mass spectrometry, which identifies molecules based on their mass, and various spectroscopy methods, analyzing how a material interacts with light, provide this detailed information, helping us understand the specific chemical connections and their influence on the material’s properties.

Putting Crosslinking to Work: Applications

Crosslinked polymers appear in a surprising number of places:

| Application | Example | Benefit of Crosslinking |

|---|---|---|

| Rubbers and Elastomers | Car tires, seals | Increased elasticity and durability |

| Thermosetting Plastics | Adhesives, coatings, structural components | High strength, heat resistance, and stability |

| Protein Analysis | Studying protein structure and interactions | Helps map complex protein structures |

| Hydrogels | Wound dressings, contact lenses, drug delivery | High absorbency, biocompatibility |

Emerging Trends and Future Prospects

The field of crosslinked polymers is constantly evolving. Researchers are exploring several exciting areas:

- Biomaterials and Tissue Engineering: Scientists explore crosslinking to engineer tissues and organs, potentially revolutionizing medicine.

- 3D Printing: Crosslinking is key to giving 3D-printed objects the necessary strength and durability.

- Advanced Crosslinking Agents: New agents offer greater control over the process, leading to more tailored material properties.

- Self-Healing Materials: Researchers investigate how crosslinking can help create these remarkable materials.

Calculating Crosslinking: A Deeper Dive

Determining the extent of crosslinking, often referred to as “degree of crosslinking,” “crosslink density,” or “extent of crosslinking,” is crucial because it directly affects material behavior. This section explores methods for measuring crosslinking.

1. Rheological Analysis: Probing Polymer Behavior

Rheological analysis assesses how a material responds to applied forces, providing insights into its internal structure. Instruments called rheometers apply controlled forces and measure the material’s response, including viscosity (resistance to flow) and elasticity (ability to bounce back after deformation). Highly crosslinked materials tend to be more viscous and less elastic due to the interconnected network. By analyzing these properties under different forces, we can infer the degree of crosslinking and predict material performance.

2. Crosslinking Mass Spectrometry (XL-MS): Mapping Protein Interactions

XL-MS is a powerful technique for studying protein interactions and 3D structures. It involves introducing a chemical crosslinker that binds to proteins in close proximity. The proteins are then fragmented, and the crosslinked pieces are identified using mass spectrometry, revealing interaction sites. This information helps map protein structures and understand their function within complex biological processes. Ongoing research continually refines XL-MS for more detailed insights.

Thinking About the Bigger Picture

While these techniques are powerful, our understanding of crosslinking is constantly evolving. Ongoing research continues to expand our ability to measure and interpret crosslinking data, leading to new discoveries and improved methods for analyzing complex materials and biological systems.

Identifying Crosslinked Polymers: Telltale Signs

This section explores the observable characteristics indicating whether a polymer is crosslinked.

Clues to Look For:

Crosslinking creates a network within the polymer, affecting its behavior in distinct ways:

1. Solubility: Uncrosslinked polymers typically dissolve in appropriate solvents, while crosslinked polymers often remain insoluble, resembling a fishing net resisting dissolution.

2. Heat Response: Uncrosslinked polymers soften and melt when heated, whereas crosslinked polymers tend to decompose or char, similar to wood, due to the strong interconnections preventing flow.

3. Stretching: Crosslinked polymers exhibit greater stiffness and resistance to stretching compared to their uncrosslinked counterparts, which are more pliable.

4. Swelling: Crosslinked polymers resist swelling in solvents due to the interconnected network, unlike uncrosslinked polymers, which absorb solvent and expand significantly.

The Importance of Identifying Crosslinking

Understanding whether a polymer is crosslinked is essential for determining its properties and potential applications. Crosslinking underlies the properties of numerous everyday materials, including car tires, furniture coatings, and medical devices, demonstrating its practical significance. While these tests provide strong clues, ongoing research continues to advance our understanding of polymers and their behavior.

Measuring the Degree of Crosslinking: A Comprehensive Guide

This section examines techniques for determining how much crosslinking has occurred, providing insights into material properties.

1. Rheological Analysis: Assessing Polymer Response to Stress

Rheology examines how materials deform and flow under stress. Instruments called rheometers apply precise forces and measure the material’s response. Highly crosslinked polymers behave more like a rubber ball, exhibiting greater stiffness and elasticity, while less crosslinked polymers resemble jelly, being more fluid. Comparing the rheological behavior of crosslinked and uncrosslinked versions provides insights into the extent of crosslinking and predicts material behavior under various conditions.

2. Swelling Analysis: Measuring Solvent Uptake

Swelling analysis involves exposing a polymer to a solvent and measuring the degree of expansion. Crosslinks act as bridges, restricting solvent penetration and limiting swelling. Highly crosslinked polymers swell less than their less crosslinked counterparts. This straightforward method provides a valuable initial assessment of the degree of crosslinking.

3. Spectroscopic Techniques: A Molecular-Level View

Spectroscopic techniques, such as NMR and IR spectroscopy, analyze interactions between materials and light or energy, providing detailed information about chemical bonds. These techniques help identify specific chemical groups involved in crosslinks, offering insights into the type and extent of crosslinking, akin to obtaining a high-definition image of the molecular structure.

The Significance of Measuring Crosslinking

Determining the degree of crosslinking is crucial for tailoring materials for specific applications and ensuring product quality. It influences the durability of car tires, the biocompatibility of medical implants, and the effectiveness of drug delivery systems. Ongoing research continues to refine our understanding and measurement techniques for crosslinking, highlighting the dynamic nature of this important field.

- Unlock Elemental 2 Secrets: Actionable Insights Now - April 2, 2025

- Lot’s Wife’s Name: Unveiling the Mystery of Sodom’s Fall - April 2, 2025

- Photocell Sensors: A Complete Guide for Selection and Implementation - April 2, 2025

1 thought on “Finding Crosslinked Polymers: Methods, Analysis, and Applications”

Comments are closed.