Ensuring the safety and compliance of electrical installations is paramount, and understanding conductor ampacity plays a crucial role. NEC 310.15(B)(16) (formerly 310.16) provides the guidelines for determining the safe current-carrying capacity of conductors. This comprehensive guide breaks down the technical aspects of this vital code section, empowering you to make informed decisions for your electrical projects. Whether you’re renovating your home or designing a complex electrical system, understanding conductor ampacity is essential for preventing hazards and ensuring long-term reliability.

What is Conductor Ampacity and Why is it Crucial?

Conductor ampacity is the maximum amount of electrical current a wire can safely conduct continuously without exceeding its temperature rating. Think of it like a water pipe – a larger pipe can handle more water flow. Similarly, a thicker wire can handle more electrical current. Exceeding the ampacity limit can lead to overheating, insulation breakdown, and potentially fire hazards. NEC 310.15(B)(16) is designed to prevent these risks by providing safe current limits based on various factors. This isn’t just about following rules—it’s about safeguarding lives and property.

Key Factors Affecting Ampacity

Several factors influence a conductor’s ampacity. These include:

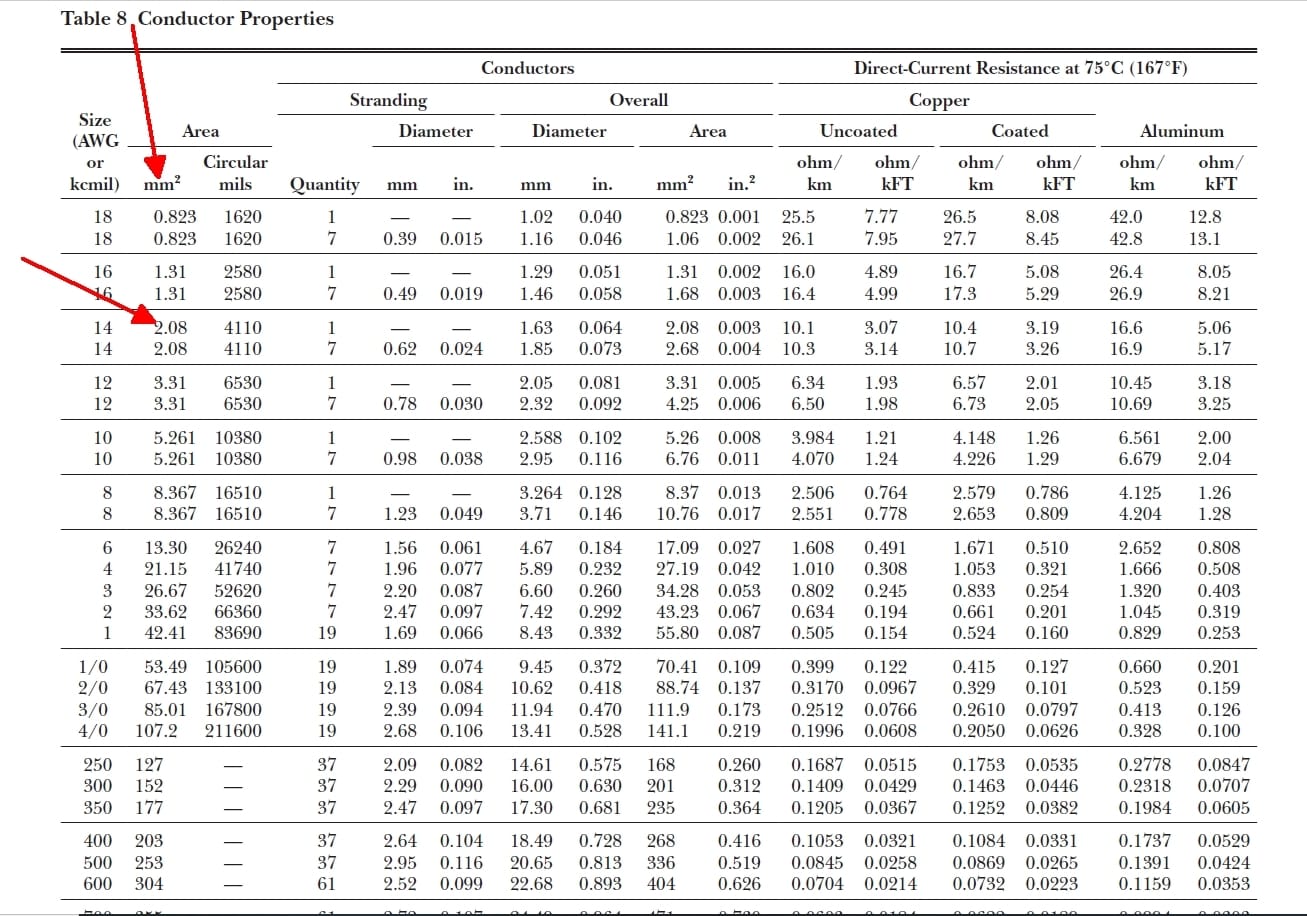

Conductor Material: Copper exhibits higher conductivity than aluminum, meaning a copper wire of a specific gauge can typically carry more current than an aluminum wire of the same size.

Insulation Type: Different insulation materials have varying temperature ratings. For instance, THHN insulation can withstand higher temperatures than THWN, influencing the conductor’s ampacity.

Ambient Temperature: Higher ambient temperatures reduce a conductor’s ability to dissipate heat, effectively lowering its ampacity. The ampacity tables in the NEC typically assume an ambient temperature of 30°C (86°F).

Number of Conductors in a Raceway: When conductors are bundled together in a conduit or raceway, they retain more heat. This necessitates applying derating factors to account for the reduced heat dissipation.

Installation Method: How a conductor is installed—whether in free air, a raceway, a cable, or directly buried—affects its ability to dissipate heat and consequently impacts its ampacity.

Navigating NEC 310.15(B)(16): A Step-by-Step Approach

Determine the Applicable NEC Edition: Always consult the most recent edition of the NEC, as tables and regulations can be updated.

Identify Conductor Material and Insulation Type: Locate the appropriate table in the NEC based on whether you are using copper or aluminum conductors and the specific type of insulation.

Determine Wire Gauge: Determine the required wire gauge (AWG) based on your circuit’s current demands.

Consider Ambient Temperature: If the ambient temperature exceeds 30°C (86°F), apply the appropriate correction factor from NEC Table 310.15(B)(2)(a). Higher temperatures necessitate lower ampacity ratings.

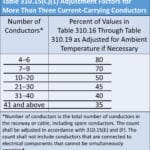

Account for Conductor Bundling: If more than three current-carrying conductors are in a single raceway, use the derating factors from Table 310.15(B)(3)(a). Bundling reduces the effective ampacity of each conductor.

Apply Correction Factors: Multiply the base ampacity value from Table 310.15(B)(16) by the applicable correction factors to arrive at the adjusted ampacity rating.

Decoding the Ampacity Charts

NEC Table 310.15(B)(16) presents ampacity values for insulated conductors rated up to 2000V. The table is organized by wire gauge (AWG), conductor material (copper or aluminum), and insulation temperature rating (60°C, 75°C, 90°C). Ensure you select the correct column based on your specific conductor and insulation type.

Derating: Adjusting for Real-World Conditions

Derating factors are multipliers applied to the base ampacity values to account for conditions that can affect heat dissipation, such as elevated ambient temperature and bundled conductors. These adjustments are critical for ensuring safe operation.

Ambient Temperature Correction: Use Table 310.15(B)(2)(a) to determine the correction factor for ambient temperatures higher than 30°C (86°F). The higher the temperature, the lower the correction factor and the resulting adjusted ampacity.

Multiple Conductors in Raceway: Table 310.15(B)(3)(a) provides derating factors for bundled conductors. As the number of conductors in a raceway increases, the derating factor decreases, reducing the allowable ampacity of each conductor.

Why NEC 310.15(B)(16) Matters: Safety and Compliance

Adhering to NEC 310.15(B)(16) isn’t just about following rules—it’s about protecting people and property. Overloaded conductors can overheat, leading to insulation failure and potentially sparking fires. Using appropriately sized conductors, as determined by the ampacity tables and derating factors, safeguards against these risks. Moreover, adhering to the NEC ensures compliance with industry standards, reducing liability and facilitating inspections.

Common Misconceptions and Clarifications

“Allowable” Ampacity: The term “allowable ampacity” is outdated. Ampacity is now considered an inherent characteristic of the conductor and its environment, not something that is granted or allowed.

600-Volt Conductors: Previous versions of the NEC had an oversight regarding 600-volt conductors. This has been rectified in more recent editions, so ensure you’re using the most up-to-date code information.

Oversized Lugs: A common misconception is that using oversized lugs increases the ampacity of a conductor. This is not true. The conductor’s ampacity is determined by the conductor itself and its environment, not the lug it’s connected to. Termination temperature limits, governed by NEC 110.14(C), also play a crucial role and must be considered in conjunction with ampacity ratings. “Per NEC 110.14(C) I must determine the ampacity of the termination based upon NEC table 310.16.” This highlights the interdependence of various NEC articles.

Beyond the Charts: Advanced Considerations

While the ampacity charts provide a solid foundation, there are nuanced situations that require additional considerations. For example, the effects of harmonics, voltage drop, and specific installation conditions might necessitate further adjustments or professional guidance.

Staying Current: The Importance of NEC Updates

The NEC is revised regularly to reflect the latest research and best practices. Staying informed about these updates is vital for ensuring the safety and compliance of your electrical installations. Consider it like updating software – it keeps everything running smoothly and securely. Remember, if you’re unsure about any aspect of conductor sizing or ampacity calculations, consulting a qualified electrician is always the best course of action.

If you are looking to exercise your brain with some challenging and engaging puzzles, you might want to have a go at our neural transmitters crossword or try our multitas!

- Red Cloud, NE: Discover Willa Cather’s Legacy - April 11, 2025

- Remember Old Social Media Sites? Their Rise and Fall - April 11, 2025

- How many days till Feb 3?Accurate Countdowns & Tools - April 11, 2025