Aluminum is ubiquitous, found in everything from beverage cans to airplanes. Its remarkable versatility stems largely from its unique combination of low density and impressive strength. Understanding aluminum density is crucial for engineers, designers, and anyone working with this versatile metal. This guide explores the density of aluminum, its practical implications, common conversions, and the exciting future of aluminum research.

What is Density and Why Does it Matter?

Density measures how much mass is packed into a given volume. Imagine holding two identically sized blocks, one aluminum and one lead. The lead feels significantly heavier because it has a higher density—more atoms crammed into the same space. In the US, we typically express density in pounds per cubic inch (lb/in³), indicating the weight of one cubic inch of material.

Aluminum’s density is approximately 0.0975 lb/in³, roughly one-third that of steel. This low density is a game-changer in various industries, offering significant advantages:

- Weight Savings: Aluminum’s low density enables lighter vehicles, from cars and airplanes to bicycles, leading to improved fuel efficiency, reduced wear and tear, and lower transportation costs.

- High Strength-to-Weight Ratio: Despite its lightness, aluminum is surprisingly strong. This desirable strength-to-weight ratio makes it ideal for applications demanding both strength and minimal weight, such as aircraft wings and high-performance bicycles. Some experts believe certain aluminum alloys surpass the strength of some steels while remaining significantly lighter.

- Corrosion Resistance: Aluminum naturally forms a thin, protective oxide layer, preventing rust and making it suitable for outdoor applications like window frames and building facades. Ongoing research suggests this corrosion resistance can be further enhanced through advanced alloy development, extending its lifespan in harsh environments.

Key Points About Aluminum Density

- Density measures how tightly packed a material’s atoms are.

- Aluminum’s density is ~0.0975 lb/in³.

- Low density contributes to weight savings, high strength-to-weight ratio, and corrosion resistance.

Aluminum Density Conversions

While lb/in³ is common in the US, other units are often used. Here’s a conversion table:

| Unit | Value |

|---|---|

| lb/in³ | 0.0975 |

| g/cm³ | 2.7 |

| kg/m³ | 2700 |

| lb/ft³ | 168.4931 |

| oz/in³ | 1.5601 |

This table allows you to use the most appropriate units for your specific needs. For instance, scientific contexts often utilize g/cm³ or kg/m³. Explore our conversion factors and problem-solving lab 2 report sheet answers for further assistance with unit conversions.

The Future of Aluminum and Density

Materials science is constantly evolving. Researchers continually seek to improve aluminum’s properties, exploring new alloys and manufacturing processes. While we understand aluminum density well, future discoveries may yield materials with even lower densities and enhanced performance. This exciting field holds untold potential for lightweighting innovations.

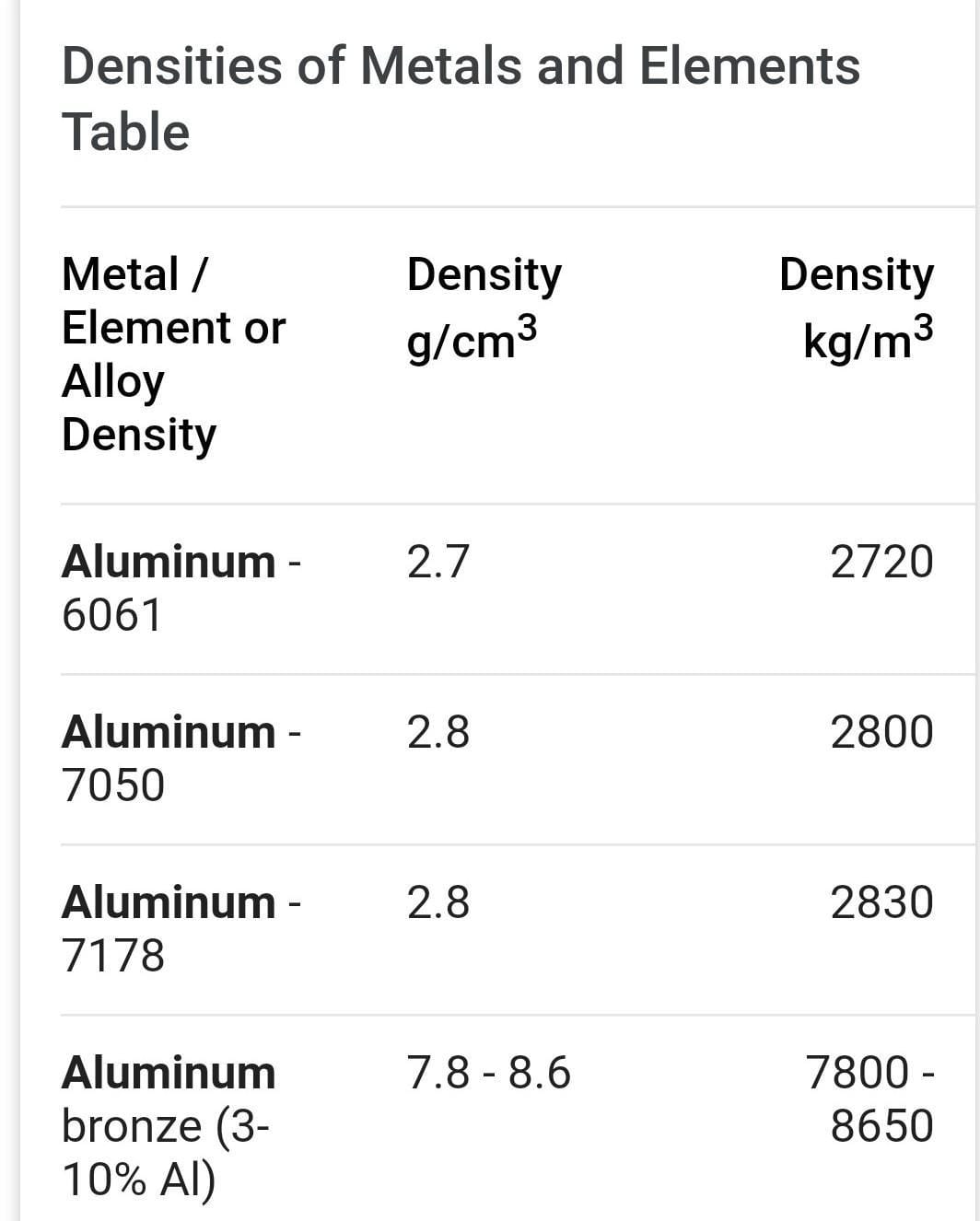

Diving Deeper: Specific Aluminum Alloys

7075-T6 Aluminum: Density and Applications

7075-T6 aluminum, a high-strength alloy, has a density of approximately 0.101 lb/in³, slightly higher than pure aluminum due to alloying elements like zinc, magnesium, and copper. This blend of lightweight and strength makes it ideal for demanding applications.

Key Features of 7075-T6:

- Density: ~0.101 lb/in³

- Strength: High

- Hardness: High

Applications:

- Aircraft structures (wings, fuselage, gears)

- High-performance vehicles

- Sporting goods (baseball bats, bicycle frames)

- Precision tools

Pros:

- Excellent strength-to-weight ratio

- Corrosion resistance

- Good machinability

Cons:

- Higher cost than pure aluminum

- Potential for brittleness under certain conditions

While 0.101 lb/in³ is generally accepted, slight variations may occur due to manufacturing processes. Ongoing research continues to refine our understanding of materials science, and even established figures may be subject to minor revisions in the future.

5052 Aluminum: Density and Applications

5052 aluminum is known for its excellent corrosion resistance and formability, making it a popular choice for marine and chemical environments. Its density is approximately 0.0968 lb/in³ (2.68 g/cm³). This relatively low density contributes to its appeal in various applications.

Key Features of 5052:

- Density: ~0.0968 lb/in³ (~2.68 g/cm³)

- Composition: ~97.25% Al, 2.5% Mg, 0.25% Cr

- Properties: Good workability, corrosion resistant, non-heat-treatable

Applications:

- Marine applications (boat hulls, etc.)

- Chemical processing equipment

- Forming operations

While minor variations in grain size can slightly influence density, it generally remains consistent around 0.097 lb/in³. This consistency is crucial for engineers and designers who rely on predictable material properties. Ongoing research continues to explore the nuances of 5052 aluminum’s properties, ensuring its continued reliability and performance in demanding environments.

Conclusion

Understanding aluminum density is fundamental to working with this versatile metal. From lightweighting in transportation to corrosion resistance in marine environments, aluminum’s density plays a crucial role. As research advances, we can expect further innovations and applications for this remarkable material.

- SYBAU See You Baby Meaning: Gen Z Slang Evolves - July 1, 2025

- Unlock Your Inner Youth: Lifestyle Secrets for a Vibrant Life - July 1, 2025

- Decode SYBAU Meaning: Gen Z Slang Explained - July 1, 2025

1 thought on “Aluminum Density (lb/in3): A Practical Guide with Conversions and Applications”

Comments are closed.