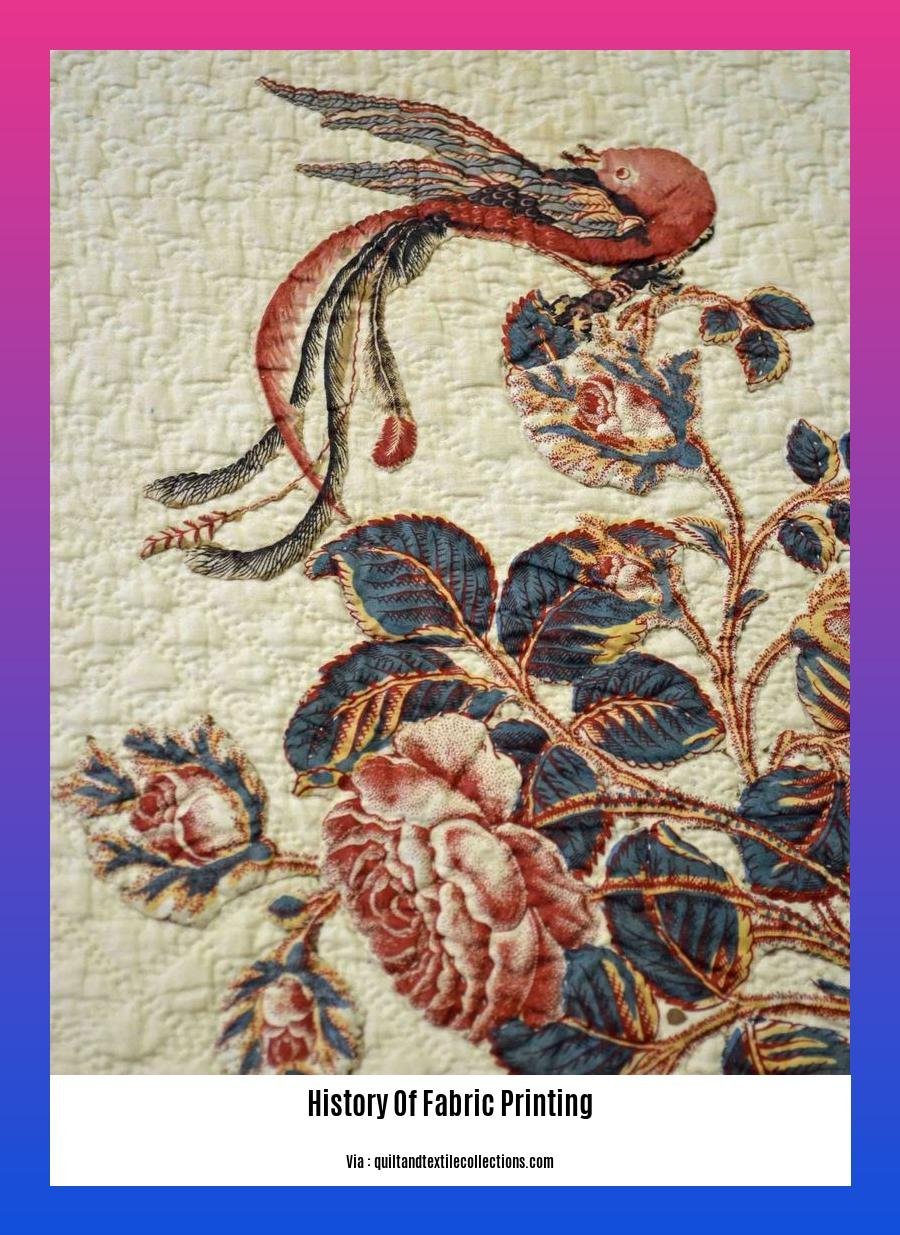

Embark on a captivating journey into the world of fabric printing in [Exploring the History of Fabric Printing: A Journey Through Time and Textiles]. From ancient dyeing techniques to modern digital printing, this comprehensive article unveils the rich tapestry of colors, patterns, and stories woven into the fabric of human history. Join us as we explore the evolution of this transformative art form, tracing its impact on fashion, culture, and everyday life.

Key Takeaways:

- Textile printing emerged in India and Mesopotamia around 2000 BCE.

- Woodblock printing, developed in China in 220 CE, spread throughout Asia, India, and Europe.

- The industrial revolution brought about modern printing techniques like roller and flat screen printing.

History of Fabric Printing: Threads of Tradition and Innovation

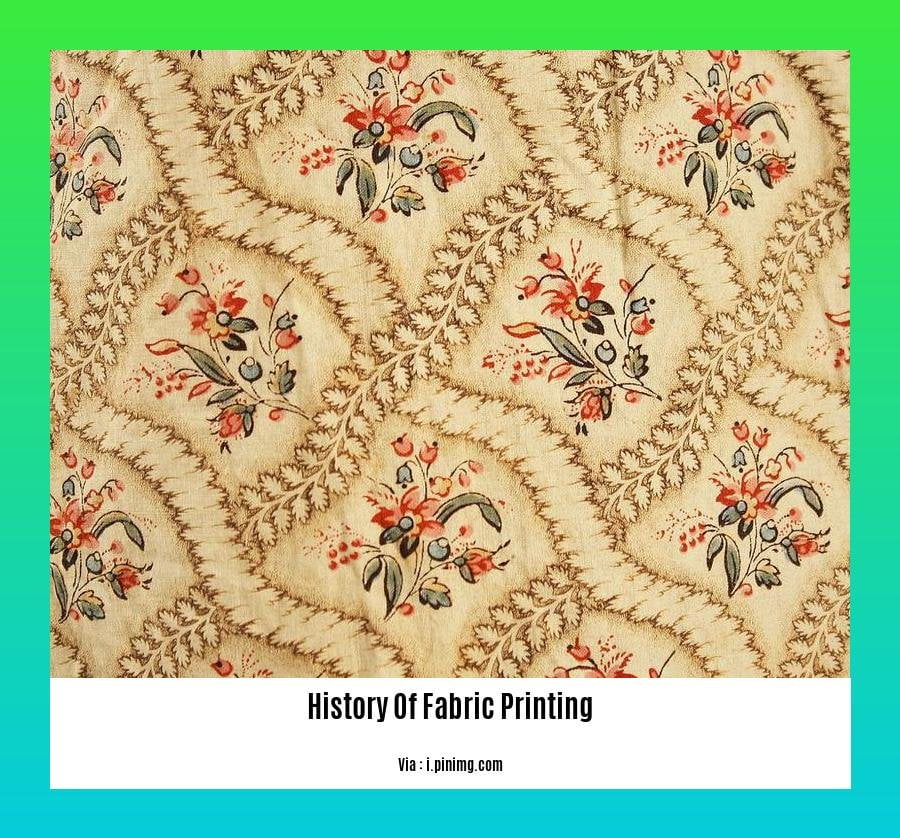

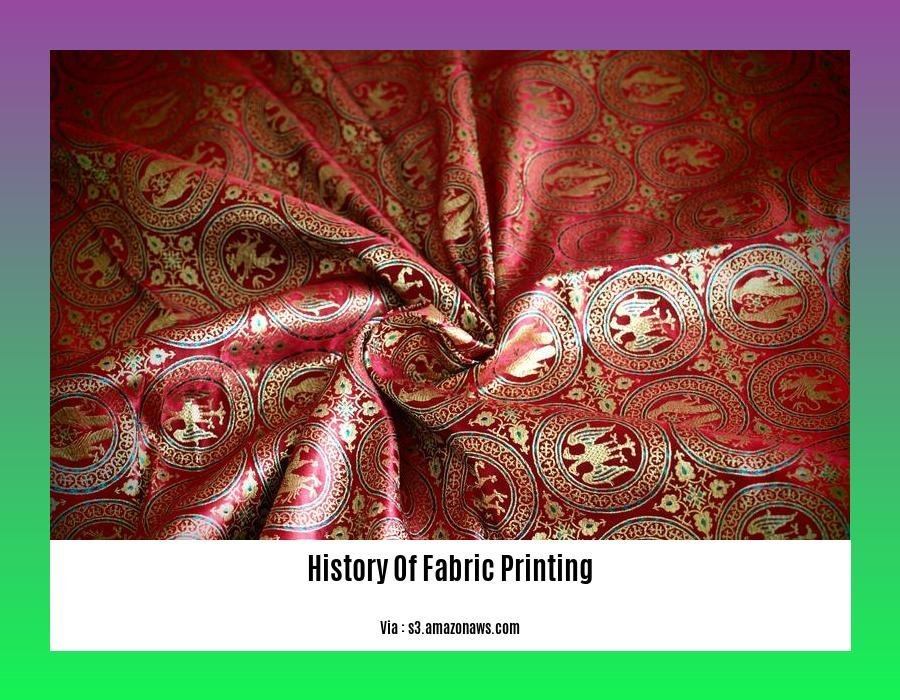

Unfolding the story of fabric printing is like embarking on a captivating journey through time and textiles. Its roots trace back to ancient civilizations like India and Mesopotamia, where artisans employed resist dyeing and block printing to create mesmerizing patterns on fabrics. In China, woodblock printing flourished as early as 220 CE, becoming a staple textile printing method across Asia, India, and Europe.

The advent of the Industrial Revolution ushered in a new era of fabric printing with the introduction of mechanized techniques such as roller and flat screen printing. These innovations propelled the industry forward, enabling mass production and intricate designs that were previously impossible to achieve.

Over the centuries, fabric printing has evolved into a diverse and dynamic craft, influenced by cultural traditions, technological advancements, and artistic movements. From the vibrant ikats of Indonesia to the intricate Batik of Java, each region has developed its unique printing techniques, showcasing the rich tapestry of global textile heritage.

Woodblock Printing: A Legacy of Precision

Emerging in China during the Han dynasty, woodblock printing revolutionized fabric printing by allowing for intricate designs and mass production. Artisans meticulously carved intricate patterns onto wooden blocks, which were then inked and pressed onto fabrics, creating vibrant and long-lasting prints.

Roller Printing: A Revolution in Efficiency

The invention of the roller printing machine in the late 18th century marked a significant milestone in the history of fabric printing. This innovative technology enabled continuous printing of fabrics using engraved rollers, increasing efficiency and reducing production costs.

Screen Printing: A Versatile Technique

Invented in the early 20th century, screen printing utilizes a mesh screen to transfer ink onto fabrics. This technique offers versatility and precision, allowing for the creation of complex designs and patterns on a wide range of materials.

Digital Printing: A New Frontier in Innovation

The advent of digital printing in the late 20th century opened up a new realm of possibilities in fabric printing. This cutting-edge technology allows for on-demand printing, intricate designs, and precise color matching, transforming the industry and enabling limitless creativity.

As we delve deeper into the history of fabric printing, we uncover a fascinating narrative of innovation, artistry, and cultural exchange. From ancient resist dyeing to the latest digital techniques, this remarkable craft continues to captivate and inspire, weaving together the past, present, and future of textile design.

Learn the fascinating history of cranes and witness how these extraordinary machines have revolutionized construction and engineering throughout the ages.

Discover the rich history of cranes machines, from their humble beginnings to their modern-day marvels, and explore their profound impact on shaping cities and skylines around the world.

Unravel the captivating history of dreadlocks and slavery, shedding light on the deep-rooted cultural and social significance of this hairstyle, from its origins in ancient Africa to its role in the struggle for freedom and identity during the slave era.

Technological Advancements: The Industrial Revolution brought mechanization to fabric printing, enabling mass production and introducing innovative printing methods like roller printing and screen printing.

Once upon a time, in the realms of textile history, a transformative chapter unfolded during the Industrial Revolution. A whirlwind of technological advancements swept across the fabric printing landscape, heralding an era of mass production and innovative printing techniques that would forever reshape the industry.

Power looms, the pioneers of mechanization, revolutionized the textile landscape. These ingenious machines wove intricate patterns with unmatched speed and precision, weaving a tapestry of efficiency into the fabric of textile production.

Steam power emerged as a driving force, propelling textile manufacturing forward. With its relentless energy, it fueled machines, accelerated processes, and fueled the fires of innovation that ignited the industry.

The cotton gin, a remarkable invention, revolutionized cotton processing. It deftly separated cotton fibers from their seeds, unraveling a new era of efficiency in cotton production that would shape the textile landscape for years to come.

The Industrial Revolution transcended the boundaries of textile production, leaving an indelible mark on banking, communication, and transportation. This interconnected web of advancements propelled the fabric industry forward, creating a fertile ground for innovation and growth.

Key Takeaways:

The Industrial Revolution ushered in an era of mechanization, transforming fabric printing with power looms and steam-powered machines.

Innovations like the cotton gin revolutionized cotton processing, increasing efficiency and productivity.

Banking, communication, and transportation advancements supported the growth and expansion of the fabric industry during this period.

Mechanization enabled mass production, making fabrics more accessible and affordable for consumers.

The Industrial Revolution laid the groundwork for future advancements in fabric printing, paving the way for intricate designs and diverse printing techniques.

Sources:

[1] https://knowingfabric.com/how-technological-advancements-revolutionized-fabric-production

[2]

Synthetic Dyes and New Materials: The development of synthetic dyes and fabrics like nylon and polyester revolutionized the industry, expanding the range of colors and textures available to designers.

Indeed, synthetic dyes and new materials had a transformative impact on the textile industry. Let’s delve into this chapter of the textile story.

In the mid-19th century, a serendipitous discovery by William Henry Perkin, a young chemistry student, led to the birth of the synthetic dye industry. His creation of mauveine, the first synthetic dye, marked a turning point in textile coloration. This breakthrough paved the way for a kaleidoscope of synthetic dyes, each boasting unique hues and properties.

The development of synthetic dyes coincided with the rise of new materials like nylon and polyester. These man-made fibers, with their inherent strength, durability, and versatility, revolutionized the textile landscape. Their ability to retain vibrant colors from synthetic dyes opened up a world of possibilities for designers, who could now explore a broader spectrum of colors and textures.

The advent of synthetic dyes also had far-reaching implications for the textile manufacturing process. Traditional dyeing methods, which relied on natural dyes extracted from plants and animals, were often time-consuming and inconsistent. Synthetic dyes, on the other hand, offered greater control over color, consistency, and reproducibility.

Key Takeaways:

- Synthetic dyes:

- Discovery of mauveine by William Henry Perkin in the mid-19th century.

- Replaced natural dyes, offering a wider range of colors and improved consistency.

- New materials:

- Introduction of synthetic fibers like nylon and polyester.

- Stronger, more durable, and versatile than natural fibers.

- Ability to retain vibrant colors from synthetic dyes.

- Textile manufacturing:

- Revolutionized the dyeing process, enabling greater control and reproducibility.

- Increased efficiency and productivity in textile production.

URL Sources:

Contemporary Trends: In recent years, sustainable practices and digital printing technologies have gained prominence, reflecting a growing awareness of environmental and ethical considerations in the textile industry.

In the realm of fabric printing, recent years have ushered in a wave of transformative trends that reflect a growing consciousness of environmental and ethical considerations. At the forefront of this movement lies the adoption of sustainable practices and the embrace of digital printing technologies.

Digital Printing: A Revolution in Sustainability

Digital printing has emerged as a game-changer in the textile industry, heralding a new era of sustainable fabric production. Unlike traditional printing methods that rely on copious amounts of water and energy, digital printing operates with remarkable efficiency, slashing water usage by a whopping 98% and boasting a 50% reduction in energy consumption.

Environmental Impact of Digital Printing

The environmental benefits of digital printing are far-reaching. By minimizing water usage, this innovative technology alleviates the strain on freshwater resources, a critical issue in many regions grappling with water scarcity. Furthermore, the reduced energy consumption translates to a significant decrease in greenhouse gas emissions, contributing to the fight against climate change.

Ethical Considerations in Sustainable Fabric Printing

The textile industry has long been plagued by ethical concerns, including the use of harmful chemicals and the exploitation of workers in developing countries. Sustainable practices in fabric printing address these issues head-on. By employing eco-friendly dyes and inks, the industry can mitigate the release of toxic substances into the environment, safeguarding the health of workers and consumers alike. Additionally, ethical sourcing practices ensure fair treatment and compensation for workers throughout the supply chain.

Key Takeaways:

- Digital printing significantly reduces water usage, conserving a precious resource and mitigating water scarcity.

- Digital printing boasts a 50% reduction in energy consumption, lowering carbon emissions and contributing to climate change mitigation.

- Sustainable fabric printing practices prioritize the use of eco-friendly dyes and inks, safeguarding worker and consumer health.

- Ethical sourcing practices ensure fair treatment and compensation for workers throughout the supply chain, promoting social responsibility in the textile industry.

Sources:

[1] https://www.sciencedirect.com/science/article/pii/B9780128214831000176

[2]

FAQ

Q1: What role did the Industrial Revolution play in the evolution of fabric printing?

A1: The Industrial Revolution brought about groundbreaking advancements in fabric production, introducing power looms, and automating various processes. These innovations revolutionized the industry, increasing efficiency, productivity, and output while reducing labor costs.

Q2: How did the advent of synthetic dyes impact the textile industry?

A2: The discovery of synthetic dyes, particularly Mauveine in the 1850s, revolutionized the textile industry. It led to the rapid growth of the chemical and dyeing industries, enabling the production of a vast array of colors and hues. Azo dyes, the most commonly used class of dyes in textiles, are known for their affordability, intensity, and color fastness.

Q3: What is the significance of digital printing technology in modern textile printing?

A3: Digital printing technology has transformed the textile printing landscape. Compared to traditional rotary print methods, it offers significant environmental benefits. With a water usage of only 1 liter per linear meter (compared to 50-100 liters in traditional methods), digital printing conserves water resources. Additionally, it leads to energy savings of up to 50% and reduces CO2 emissions by up to 90%.

Q4: How did the introduction of woodblock printing influence fabric printing practices?

A4: Woodblock printing, developed in China in 220 CE, became a widely adopted textile printing method across Asia, India, and Europe. It involved carving designs onto wooden blocks and using them to transfer ink onto fabric. This technique enabled the production of intricate patterns and designs, fostering a rich tradition of block printing in various cultures.

Q5: What are some ancient fabric printing methods still practiced today?

A5: Traditional fabric printing methods, such as resist dyeing and block printing, continue to be practiced in various parts of the world, preserving cultural heritage and artisanal skills. Resist dyeing, a technique that involves creating patterns by selectively preventing dye from reaching certain areas of the fabric, has ancient roots in India and Japan. Block printing, utilizing carved wooden blocks to transfer ink onto fabric, remains a popular technique in India and other regions, showcasing intricate designs and vibrant colors.

- Senior at What Age: Benefits & Eligibility Guide - March 29, 2025

- Unlocking Senior Benefits: How Old is a Senior? Your Complete Guide - March 29, 2025

- Master Russian Politeness:A Guide to Saying Please - March 29, 2025