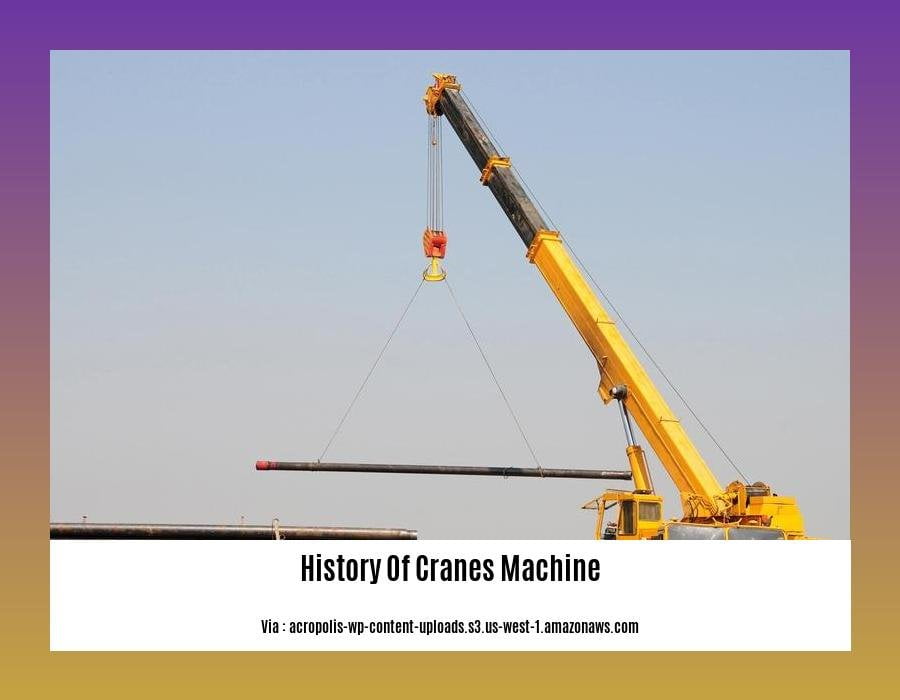

Get ready to embark on a captivating journey through the annals of history as we unravel the intriguing tale of crane machines in our article, “Unraveling the History of Crane Machines: A Journey of Innovation and Engineering Ingenuity.” Delve into the fascinating world of these ingenious inventions as we trace their evolution from humble origins to the sophisticated automated wonders we encounter today. From their initial use in ancient civilizations for construction and warfare to their transformation into beloved amusement arcade fixtures, crane machines have played a pivotal role in shaping our world, leaving an indelible mark on both industry and entertainment. So, buckle up and prepare to be amazed as we uncover the extraordinary history of these iconic machines!

Key Takeaways:

- From the onset, cranes were simple pulley systems utilized by ancient Mesopotamians over 3,500 years ago.

- Ancient Greeks further advanced the crane’s capabilities, implementing them in temple construction to lift tongs and iron during the 6th century BC.

- Archimedes of Syracuse made a notable contribution with his invention of compound pulleys around 287-212 BC, enabling him to lift a warship with its crew.

History of Crane Machines

[History of crane machines] can be traced back to ancient times, serving as an essential tool in construction, transportation, and warfare.

Ancient Origins

- Lifting to New Heights

- Simple pulley systems emerged in ancient Mesopotamia around 1500 BC, serving as the foundation for early crane mechanisms.

- The ancient Greeks transformed this technology in 515 BCE, introducing the first cranes to facilitate temple construction.

Pulleys and the Power of Compound Forces

- Archimedes’ Innovation

- Archimedes (287-212 BC), a renowned Greek mathematician and inventor, introduced compound pulleys, amplifying lifting power and enabling the movement of massive objects such as warships.

Cranes in the Medieval World

- Medieval Engineering

- During the medieval era, advancements in engineering led to larger and more robust cranes.

- These medieval cranes, often powered by human or animal labor, were crucial in constructing towering cathedrals and castles.

The Rise of Industrial Revolution Cranes

- Steam-Powered Strength

- The Industrial Revolution marked a pivotal moment in crane development.

- Steam engines provided the power to operate larger cranes, revolutionizing construction and enabling the building of iconic structures like the Eiffel Tower.

Modern Cranes: Automation and Efficiency

- Hydraulic and Electric Cranes

- Hydraulic and electric power systems replaced steam, offering greater control and efficiency in lifting operations.

- Advanced control systems and automation features enhanced safety and precision, leading to today’s sophisticated crane designs.

Conclusion

From the humble beginnings of simple lifting mechanisms to the marvels of modern automated cranes, this journey highlights the remarkable history of crane machines. Their evolution reflects human ingenuity, engineering prowess, and the insatiable desire to build and innovate.

History buffs, interested in the evolution of mechanical marvels? Dive into the fascinating history of cranes, from their humble beginnings to the modern giants that shape our skylines here: ../history-of-cranes

Do you know the intricate story behind dreadlocks and their connection to slavery? Explore the compelling history of dreadlocks, shedding light on their cultural significance and resilience in the face of adversity here: ../history-of-dreadlocks-slavery

Textile enthusiasts, ready to journey through the vibrant world of fabric printing? Discover the captivating history of fabric printing, tracing its origins and marveling at the artistry and innovation that transformed textiles into masterpieces here: ../history-of-fabric-printing

Diversification of Applications: Discuss the expansion of crane machines into diverse fields beyond construction, such as manufacturing, mining, shipping, and even space exploration, showcasing their versatility and adaptability.

Cranes have transcended their traditional role in construction. Their versatility has led to their adoption in a variety of industries, each presenting unique challenges and requirements. Let’s explore their diversification:

Manufacturing:

In the bustling world of manufacturing, cranes play a crucial role in moving raw materials, heavy machinery, and finished products. They ensure efficient material handling, optimizing production processes. Their precision and lifting capacity make them indispensable in assembling large-scale machinery, such as aircraft or automobiles.

Mining:

Cranes are indispensable in the mining industry. They facilitate the extraction and transportation of minerals, coal, and other valuable resources. Their ability to operate in harsh conditions and lift massive loads makes them ideal for mining operations. From露天矿to underground mines, cranes ensure efficient and safe material handling.

Shipping:

Cranes are the backbone of shipping operations. They load and unload containers, heavy machinery, and other cargo onto and off ships. Their towering presence and precise movements ensure the smooth flow of goods, facilitating global trade and commerce.

Space Exploration:

In the realm of space exploration, cranes play a critical role in assembling, launching, and servicing spacecraft. Their ability to lift massive payloads and operate in controlled environments is essential for preparing rockets for liftoff. Cranes also aid in the construction and maintenance of launch pads and other infrastructure, enabling humanity to reach for the stars.

Key Takeaways:

- Cranes have evolved from simple lifting mechanisms to sophisticated machines used in diverse industries.

- Their versatility lies in their ability to lift heavy loads, reach great heights, and operate in various environments.

- Cranes play a crucial role in manufacturing, facilitating material handling and assembly processes.

- In mining, cranes assist in extracting and transporting minerals, ensuring efficient and safe operations.

- Cranes are vital in shipping, enabling the loading and unloading of cargo, facilitating global trade.

- Space exploration relies on cranes for assembling and launching spacecraft, pushing the boundaries of human exploration.

References:

- Types of Cranes used in Construction Works

- Crane Market – Size, Share, Trends & Growth

Safety and Regulation: Examine the evolving safety standards and regulations implemented to ensure the safe operation of crane machines, including operator training, proper maintenance, and regular inspections.

Governments worldwide recognize the paramount importance of industrial safety in achieving sustainable development. Safety and Regulation play a pivotal role in ensuring the safe operation of crane machines, safeguarding workers and preventing accidents.

Key Takeaways:

- Consistent regulations and enforcement mechanisms are crucial for effective industrial safety.

- Governments, such as OSHA in the U.S. and Rostechnadzor in Russia, have implemented comprehensive regulations for crane safety.

- Safety standards encompass operator training, proper maintenance, and regular inspections to minimize risks.

- Adherence to safety regulations not only protects workers but also enhances productivity and efficiency in crane operations.

As crane technology advanced, so did the need for stringent safety measures. Operator training emerged as a cornerstone of crane safety, ensuring that operators possess the necessary skills and knowledge to operate these machines safely and efficiently. Training programs cover various aspects, including crane mechanics, load handling techniques, and emergency procedures.

Proper maintenance is another critical aspect of crane safety. Regular inspections and maintenance help identify and address potential issues before they escalate into accidents. Maintenance procedures include visual inspections, functional testing, and scheduled servicing.

Regular inspections play a crucial role in ensuring crane safety. These inspections are conducted by qualified personnel to assess the overall condition of the crane, identify any defects or damage, and verify compliance with safety regulations.

By adhering to these safety standards and regulations, we can create a safer working environment for crane operators and ensure the smooth and efficient operation of these indispensable machines.

Sources:

The role of government, regulations, standards, and new technologies in ensuring industrial safety and security

Ensuring Industrial Safety and Security

Future Innovations: Speculate on potential future developments in crane machine technology, such as the integration of automation, artificial intelligence, and remote operation, which could revolutionize the industry.

Rapid technological advancements are transforming entire industries, and the crane industry is no exception. As we look toward the future, it’s exciting to speculate on potential innovations that could revolutionize the way cranes are designed, operated, and utilized. Here are a few intriguing possibilities:

Advanced Automation and Robotics: Future cranes could be equipped with sophisticated automation systems, enabling them to perform tasks autonomously. Robotics could play a pivotal role in automating complex lifting operations, increasing efficiency, and minimizing human error.

Artificial Intelligence (AI) for Predictive Maintenance: AI algorithms could analyze data from sensors embedded in cranes to predict potential issues and schedule maintenance proactively. This would maximize uptime, reduce downtime, and enhance overall crane safety.

Remote Operation and Telepresence: Remote operation capabilities would allow operators to control cranes from distant locations, enhancing safety in hazardous environments and enabling more efficient coordination of multiple cranes. Telepresence technologies could provide immersive experiences, allowing operators to feel as if they are physically present at the crane’s controls.

Integration with Building Information Modeling (BIM): Cranes could be integrated with BIM software, enabling real-time data sharing and coordination between design, construction, and operation teams. This integration would streamline workflows, reduce the risk of errors, and optimize the overall construction process.

Energy-Efficient and Sustainable Designs: Future cranes could incorporate energy-saving technologies, such as regenerative braking systems and hybrid powertrains, to minimize their environmental impact. Sustainable materials and manufacturing processes could also be adopted to reduce the carbon footprint of crane production and operation.

Modular and Adaptable Cranes: Cranes could be designed with modular components, allowing for easy customization and adaptation to different job requirements. This modularity would enhance flexibility, reduce downtime for reconfiguration, and enable cranes to be easily upgraded with the latest technologies.

These innovations have the potential to revolutionize the crane industry, improving safety, efficiency, and productivity. As technology continues to advance, it will be fascinating to see how these concepts are refined and implemented, shaping the future of crane operations.

Key Takeaways:

Automation and Robotics: Advanced automation and robotics will enable cranes to perform tasks autonomously, increasing efficiency, and minimizing human error.

AI for Predictive Maintenance: AI algorithms will analyze data from sensors to predict potential issues and schedule maintenance proactively, maximizing uptime and enhancing safety.

Remote Operation and Telepresence: Remote operation capabilities will allow operators to control cranes from distant locations, enhancing safety and enabling more efficient coordination.

Integration with BIM: Integration with BIM software will streamline workflows, reduce errors, and optimize the overall construction process.

Energy-Efficient Designs: Cranes will incorporate energy-saving technologies and sustainable materials to minimize their environmental impact.

Modular and Adaptable Cranes: Cranes will be designed with modular components for easy customization, reducing downtime and enabling upgrades.

Sources:

– Innovations in Crane Technology

– The Future of Cranes: How Technology is Changing the Industry

FAQ

Q1: What were the origins of crane machines?

A1: The origins of crane machines can be traced back to ancient Mesopotamia, where pulley systems were used to lift heavy objects around 1500 BC. These early cranes evolved into more sophisticated lifting mechanisms, with the first true cranes invented by the ancient Greeks in 515 BCE to aid in temple construction.

Q2: Who invented the first compound pulleys used in cranes?

A2: Archimedes of Syracuse, a renowned ancient Greek mathematician and inventor, is credited with creating the first compound pulleys around 287-212 BC. These pulleys allowed for increased lifting power, enabling the movement of heavier loads with less effort.

Q3: What are the different types of cranes used today, and where are they commonly employed?

A3: Today, there are various types of cranes designed for specific applications. Mobile cranes are self-propelled and highly maneuverable, making them suitable for construction sites and other mobile operations. Fixed cranes are stationary and are commonly used in industrial facilities and large construction projects. Marine cranes are designed for use on ships for loading and unloading cargo, while offshore cranes are heavy-duty cranes used in the oil and gas industry and offshore wind farms.

Q4: What factors should be considered when selecting a crane for a particular task?

A4: When selecting a crane for a specific task, several factors need to be taken into account. These include the capacity (maximum weight the crane can lift), reach (maximum horizontal distance the crane can reach), height (maximum vertical distance the crane can reach), and working radius (maximum distance from the crane’s base where it can lift a load).

Q5: How has modern technology influenced the development of crane machines?

A5: Modern technology has significantly influenced the development of crane machines. New crane technology offers modular designs, allowing for easy configuration to meet various needs. Intelligent service panels enable operators to diagnose and rectify faults more efficiently, enhancing maintenance planning. Compact crane designs reduce the need for expensive building renovations and can operate in tighter spaces, providing greater flexibility.

- Senior at What Age: Benefits & Eligibility Guide - March 29, 2025

- Unlocking Senior Benefits: How Old is a Senior? Your Complete Guide - March 29, 2025

- Master Russian Politeness:A Guide to Saying Please - March 29, 2025